A Message From Jim Lancaster, Owner & CEO, Lantech

Sometimes the technical noise of a buying and selling process makes it is easy to lose focus of what is important from a value perspective. So, I thought I would take a moment to share the most important things that we have learned from production environments that use stretch wrap equipment. I also want to share a more detailed explanation for how Lantech’s unique features, patented innovations, and approach to service add value for our customers.

There are three things that are really important when owning a stretch wrapper:

- The stretch wrapper must produce a good quality load that will ship successfully and additionally produce that load at the lowest cost possible. After all, that is why a company stretch wraps in the first place.

- In a production environment, uptime is critical. The machine (or system) needs to run without fail, causing virtually no downtime in the real world in which it finds itself.

- When something wears out or breaks, how fast and easy will it be to get replaced or fixed? The company you are purchasing the machine from must have the service & support system in place to ensure machines, once installed, stay running.

1. The stretch wrapper must produce a good quality load that will ship successfully.

Data and experience say there are three requirements to produce safe to ship loads:

Data and experience say there are three requirements to produce safe to ship loads:

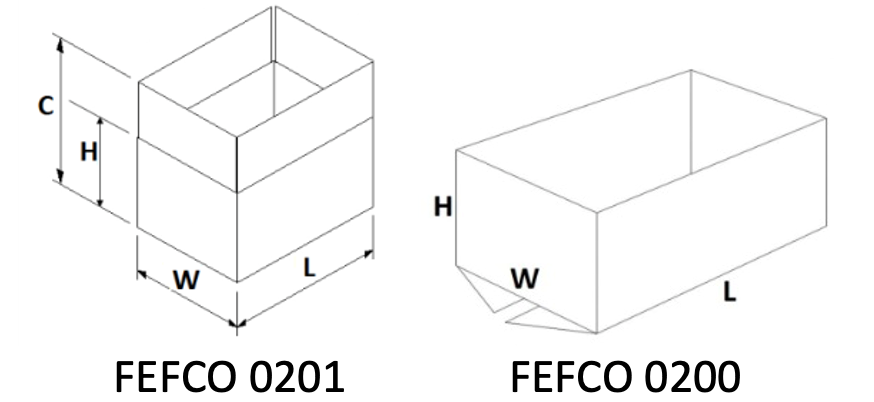

- Enough containment force spread evenly over the load. Most loads fail in the middle because they are built with top and bottom bands, where the middle has very little film and/or force applied to the load. As a result, in a vibrating truck, the top half moves relative to the bottom half, or the middle moves to one side.

- The product is attached securely to the pallet, so it does not shift off the pallet during transit.

- The beginning and ending tails are not hanging down.

Meaning the beginning tail is fully captured under subsequent layers of film and the ending tail is wiped smoothly so it adheres to the load. Otherwise, those tails can get caught in fork truck wheels, conveyor systems or AGVs.

2. The machine (or system) needs to run without fail, causing virtually no downtime in the real world in which it finds itself.

The number one cause of down time for stretch wrappers, by a large margin, is film breaks. And the number one cause of film breaks is a sharp edge on the load or pallet that punctures the film, which then propagates into a tear. Other cases of film breaks include:

- Film getting punctured or torn when contacting or wrapping over the clamps that hold the film at the beginning of the cycle.

- Film pulling or tearing out the of clamps at the beginning of the wrap cycle.

- A hole in the film, caused by a gel in the film slipping in the pre-stretch rollers.

Getting a good load, consistently, is tied to the film break problem because operators will try to fix film breaks by adjusting film tensions down, causing total containment levels to drop. To achieve an evenly contained load, the inputs required to get the machine settings right are inherently difficult. Setting top counts, bottom counts, rotation speed and film delivery system speed is easy, but doing it to create even coverage and the right containment is not. Because getting the settings balanced is difficult, virtually no one can get the settings right or even close.

So let me share with you how Lantech’s LeanWrap® machines have made a quantum leap in performance by addressing these first two issues, thereby performing at maximum uptime levels, with dramatically better, quality wrapped loads, in actual production environments, that before were only attainable in test environments. Plus, couple of other features that improve overall productivity and performance.

Metered Film Delivery® (available on RLA, SLA & QLA Automatic Stretch Wrappers)

First, film breaks were dramatically reduced by changing the way the film delivery works. Film delivery is done basically the same way by all stretch wrappers: some kind of wrap force sensing device reads the force the film is applying to the load. Some use dancer bars or roller assemblies attached to Hall Effect switches or potentiometers. Some use load cells, and others use torque feedback loops. But all of them act in the same way – if the force being applied to the load drops, they reduce the power to the FDS drive and thereby increase the wrap force. What actually happens then is when a puncture or tear starts, a sensor sees a drop in wrap force and slows the delivery motor, raising the force back up which then causes the film to continue to tear. With this type of system, virtually any puncture or tear that starts will propagate into a full film break.

Metered Film Delivery operates differently, in that it measures the perimeter of the load and pays out the length of film needed to give a predetermined amount of wrap force. Therefore, the feed rate does not change. If a puncture or small tear starts, the system is able to pass minor issues without film breaks. The other difference is that the metered system is not trying to accelerate and decelerate for every passing flat side and corner of the load. The metered system actually delivers less fluctuation in wrap force to the load, allowing for higher average force applied.

Force sensing devices start becoming less effective at 15 RPM. By the time they reach 25 RPM they are actually causing large force fluctuation out of synch with the needs of the load.

We are introducing the next generation of Metered Film Delivery this year which will deliver more containment force with less film and less film breaks. It builds upon the current Metered Film Delivery performance by further reducing overall force fluctuation, reducing load twisting, and increasing the containment force generated for each revolution of film. Next Gen Metered Film Delivery will allow our customers to use less plastic (helping them to reduce costs and reduce their environmental impact) by generating more force per revolution of film and minimizing film breaks, holding loads together better than any other film delivery system.

Load Seeking Clamp® 4.0 (Available on RLA, SLA & SA Automatic Stretch Wrappers)

The Load Seeking Clamp 4.0 (LSC 4.0), with a pneumatic bladder, practically eliminates film pulling out of the clamps. LSC 4.0’s clamp was designed to travel to the side of the load. By taking the leading tail to the side of the load, the leading tail is fully captured within the wrapped load. As a result, the film does not risk tearing as it passes over the clamps, and the containment force is maintained at the bottom of the load.

Having a Load Seeking Clamp is critical to eliminating the beginning film tail and ensuring proper Containment Force on the Pallet!

An additional benefit of this design is that the entire automation unit assembly mounts up off the floor on the conveyor making clean-up and walk paths much simpler.

Load Guardian® (Available on RLA, SLA & QLA Automatic Stretch Wrappers)

Load Guardian changes the way an operator sets up a profile to wrap a load. For all stretch wrappers without Load Guardian, the operator has to make several machine setting adjustments/decisions:

- How many top and bottom wrap counts

- Rotation speed of the film relative to the load

- Speed at which the film travels up and down to apply the film on the entire load

- Setting the film tension

- and sometimes more

As that is a difficult task to do, it results in virtually no loads being wrapped evenly because, almost always, the film tension is being set at the lowest point to not create film breaks, regardless of film type. The consequence is that most loads are shipped with too much film and not enough of evenly placed containment force – which means risky shipments.

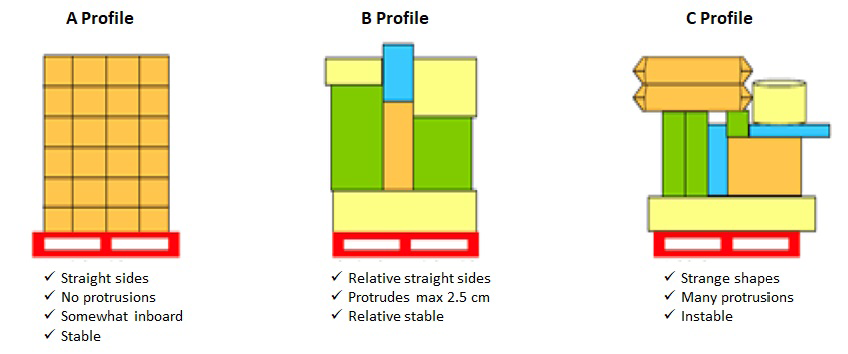

Load Guardian does not ask the operator for machine settings. It asks the operator a few questions about the load being wrapped, which are obvious by just looking at the load. It then asks the gauge of the film being used. From there Load Guardian automatically produces a profile that delivers an acceptable amount of containment force, evenly across the load. Load Guardian maintains that containment force even if the wrap force must be turned down for sub-quality film or particularly hostile load profiles. This fast set up results in a profile that can be named and color coded for easy selection later.

Pallet Grip® (Available on RLA, SLA, QLA, SA & QA Automatic Stretch Wrappers)

Pallet Grip delivers a web of film with the bottom 6 inches rolled into a tight cable of film and applies it to just the right place on the pallet, which both locks the pallet to the load and keeps the cable out of the way of fork truck forks that would otherwise destroy the connection of the film to the pallet. Testing shows a dramatic improvement in shipped load performance with Pallet Grip.

Automatic Roll Change (Option on RLA & SLA Automatic Stretch Wrappers)

Automatic Roll Change (ARC) reduces the need for operator touches caused by film exhaustion and film breaks, by holding and replenishing up to 3 additional rolls of film. The ARC provides separate access gates that allows film loading while the wrapper is running. As a result, a wrapper with ARC routinely goes days to weeks without a single minute of downtime.

The combination of these features and over 50 years of experience baked into the design of the LeanWrap machines makes them, by a large margin, the most reliable and best performing stretch wrapper available.

3. The company you are purchasing the machine from has the service & support system in place to ensure machines, once installed, stay running.

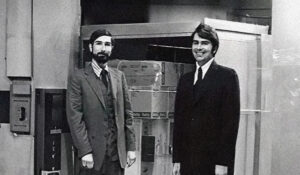

Bill Lancaster (left) and Pat Lancaster (right) founded Lantech in 1972.

I know it sounds old-fashioned, but 53 years after my father and uncle founded Lantech and the global stretch wrap industry, I still meet with new employees weekly to impart the values that have kept Lantech the dominant market leader for all these years. Lantech has been owned and led by the Lancaster family for all of those 53 years. With the third generation now involved in the business, we remain committed to the values that we believe have kept customers coming back throughout our long history.

During new employee orientation, I share the story of my father and uncle, who, despite having few resources, possessed incredible drive and passion. They refused to leave a customer’s factory until the equipment they built—sometimes right there on the customer’s facility floor—was working to the customer’s expectations. In the early years, this sometimes took a while, as the technology was new and the equipment design was rudimentary. That absolute dedication to ensuring machines, once installed, stayed running has been one of the biggest reasons customers return to us time and time again.

Lantech’s aftermarket group is focused on promptly answering calls, with friendly experts ready to help get any problems resolved quickly. Our parts team ships 85% to 95% of orders on the same day they are placed. And our highly trained service technicians are ready to assist if a machine goes down. We take care of every machine we have sold to the maximum extent possible. Every machine, back to the early 1970s, still lives with a machine specific documentation file. I tell new employees that even today, 53 years after our founding, our number one daily priority is supporting customers in down situations. Our 24/7 service team is authorized to get whatever they need, any time day or night, from anywhere in our facility to get a machine back up and running for a customer.

We are not perfect, but as a family-owned business, with long tenured loyal associates, our pride is in every machine we ship and in how we care for every customer after they take delivery. When you buy Lantech, you will always have people who care and who know more about wrapping pallets than anyone else in the world, ready to support you.