Easy….but not simple

Easy….but not simple

“It’s not complicated. I just need a stretch wrapper for regular pallets.”

We’re all busy…too busy. And none of us want to spend more time on anything than is absolutely necessary to get the task done right. So we all work to avoid over complicating tasks. That raises the risk of unknown unknowns – in other words, the questions we don’t know to ask and the details that seem insignificant to us until it’s too late.

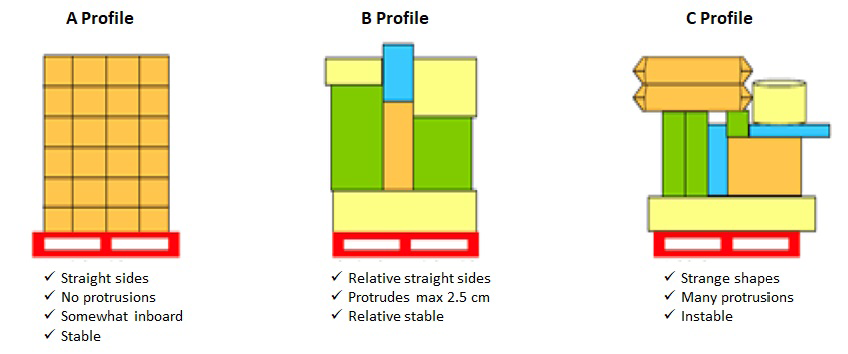

From the stretch wrapper perspective, that means understanding the important details of the load, the environment during wrapping, transport and storage, and why products are being wrapped. Even among regular CPG corrugated cases there can be differences in weight, stacking patter, head space in boxes, slip, and temperature that introduce important variables. In other industries, such as building products, the range of variables can be even larger. In nearly all cases there are simple adaptations and standard options that accommodate nearly any requirement. While many are field retrofittable, some must be installed during manufacturing. And in all cases, having a machine go immediately to work upon installation , just as envisioned, is important to avoid frustration and wasted time on the back end.

We want to help you keep your project easy without oversimplifying it and creating headaches on the backend. So here’s a list of considerations for stretch wrapping construction materials and building products to help you with your next project.

- Dust

- Weight

- Load diagonal

- UV protection

- Film tail treatment

- Moisture/water protection

Dust is an enemy of machines

Many building products are manufactured and wrapped in dusty environments – saw mills, mulch plants, and gypsum facilities are examples. Dust can lead to rapid wear of mechanical components. Special corrosion packages minimize wear in dusty environments. They typically include special motors and reducers, NEMA 4 electrical switches and control panels, precision bearings, zinc-coated conveyors, etc. Specific applications also require some additional planning. Stretch wrapping in brick and block plants, for instance, requires planning for substantial dust falling from the product onto the conveyor. That means that often straddle wrappers are best for this sort of application to avoid complications of dust falling into the mechanisms of powered turntables.

Weight of loads – from light to heavy

Not all building products are heavy. In fact, some, like foam sheathing boards and other insulation products, are quite light. In contrast, others like drywall, buckets of paint and coatings, and brick and block can be extremely heavy. Those differences impact not only conveyor specifications and design, but also the appropriate style of wrapper. Both very light and very heavy products often are best wrapped with a straddle style wrapper – but for different reasons.

Light products may spin off a pallet as a turntable rotates against the stretch film. A straddle wrapper rotates the film around the load instead. Heavy products, in contrast, would not be subject to twisting but over time might lead to excessive wear on powered turntables. Straddle wrapping eliminates the need for turntable mechanisms.

Load diagonal – not just dimension

Building products are often – simply put – really big! 4 X 8′ sheets, for instance, have a 107″ diagonal. Whether that’s sitting on a turntable or centered below a rotating wrap arm, that’s orders of magnitude different than the 63″ diagonal of a standard 40X48″ pallet.

Turntable machines offer larger diameter turntables as well as “base extensions” between the turntable and mast. Straddle wrappers are available with different arm configurations to extend the maximum wrapping diameter. Generally, these are impractical retrofits so it’s important to get this right when you order!

UV protection & tackifier

Many building products are made to be used outside. They have resistance to elements and UV degradation engineered into them. But there’s an earlier exposure to consider. Often they’re stored outside in the yards of supply houses and lumber yards. While that doesn’t deteriorate the products themselves, it can quickly lead to deterioration of the stretch film. That jeopardizes pallet integrity due to weakened stretch film. The common solution is to use stretch film which incorporates additives to prevent rapid deterioration of the film due to UV exposure.

Often construction materials are stacked and packed tightly. That introduces another consideration around film slip. You need film to have enough tack so that stacked products stay stacked on racks. On the other hand, you need enough slip to be able to move them. One example of complications comes from the cautionary tale of a carpet manufacturer that installed a new ring wrapper for rolls of carpet. These were loaded, immediately after wrapping, from floor to ceiling in an enclosed trailer for delivery. Unfortunately, they were wrapped in a high cling film with the cling layer out…..and at the receiving location, in the Southeast US during summer, the products were so completely stuck together, and the trailer so full, that the roof had to be cut to remove products!

(These articles offer more info on how stretch film is made and the role of tackifier.)

Film tail treatment

If you’ve watched our on-demand webinar “What’s the best way to stretch wrap your pallet load?” then you’re familiar with the importance of properly treating film tails. In short, they represent a quality and safety issue if they’re left dragging. Pallet wrappers typically offer a range of standard and optional solutions to secure tails to loads. For most pallets that ship inside trailers an effective and consistent solution that wipes them to the load (assuming there is some tackifier inside the film) works well.

Building products often raise another set of film tail challenges, however. Subject to buffeting by cross winds and trailer movement for extended periods at high speed, even the most expertly wiped down stretch film tail will soon start to peel off the load. That calls for a more robust solution – and the common answer is to use an optional heat sealer for securing film tails to loads of building products.

Moisture & Water Protection

Exposed transport and storage – both in lumber yards and on job sites – means that often building products are exposed to the elements. We’ve touched on ensuring load integrity by protecting film from UV deterioration. But protecting the products themselves from water and moisture is often an important consideration.

This can be as simple as plastic top sheets and tier sheets – to prevent precipitation from getting the top of load wet and protecting the bottom from water wicked up through a wooden pallet. Sometimes it requires more, however, and a common solution is to integrate two wrappers in-line. The first, a ring wrapper, wraps the product horizontally as it is conveyed through a rotating ring of stretch film. This covers the top, bottom, and two sides. Next, the load is conveyed into a traditional wrapper which wraps it vertically – covering all four sides.

This can be as simple as plastic top sheets and tier sheets – to prevent precipitation from getting the top of load wet and protecting the bottom from water wicked up through a wooden pallet. Sometimes it requires more, however, and a common solution is to integrate two wrappers in-line. The first, a ring wrapper, wraps the product horizontally as it is conveyed through a rotating ring of stretch film. This covers the top, bottom, and two sides. Next, the load is conveyed into a traditional wrapper which wraps it vertically – covering all four sides.

The right degree of stretch wrapper automation

While these are common considerations specific to stretch wrapping building products, every stretch wrapper application also raises questions regarding the degree of desired automation.

Are operators already maneuvering the products and available to secure the film to a load, start a wrap cycle, and cut the film? Or should some or all of those functions be automated?

Are the products coming at high speed off a fully automated manufacturing line or are they being manually stacked on pallets? Does handling the products raise safety considerations due to high weight or awkward size/shape? Maybe they’re even moved through areas which are inherently unsafe – perhaps even with AGVs or tugs.

If the palletization is automated then it may make sense for the pallet wrapping to be as well.

Knowing and anticipating the unknowns

The key when planning a project for stretch wrapping building products is the same as any other product – to anticipate the requirements and potential complications. That’s often the product of experience – after all, none of us can know what we don’t know.

Building products have some particular attributes to plan around, but every stretch wrapper project benefits from an experienced set of eyes and ears.

Wondering what questions you should ask? Call us. Our application experts draw on the hard-won expertise of an installed base of 70,000 machines and are available to help you plan your requirements without pushing a specific solution.

Let’s talk.

This post was published on March 7, 2017 and updated on November 9, 2018.

March 7, 2017