Shopping for a stretch wrapper can be an overwhelming process. To simplify things, consider focusing on just a few areas when you’re comparing models. Most of our customers are concerned about the safety, reliability and ease of use of a machine. They also want machine support if something goes wrong. Read below to learn how to evaluate a semi-automatic stretch wrapper.

Shopping for a stretch wrapper can be an overwhelming process. To simplify things, consider focusing on just a few areas when you’re comparing models. Most of our customers are concerned about the safety, reliability and ease of use of a machine. They also want machine support if something goes wrong. Read below to learn how to evaluate a semi-automatic stretch wrapper.

Q: Everybody says their machines are safe. How do I know for sure?

A: We believe safe stretch wrappers stand out from the crowd. Look for these characteristics:

- All wires and motors are enclosed to prevent trip, scrape or burn hazards.

- The film delivery system is:

- Located on the same side of the mast as the controls to prevent operators from walking between the mast and the load.

- Complete with guarding surrounding the rollers to prevent the operator’s hands from getting caught inside.

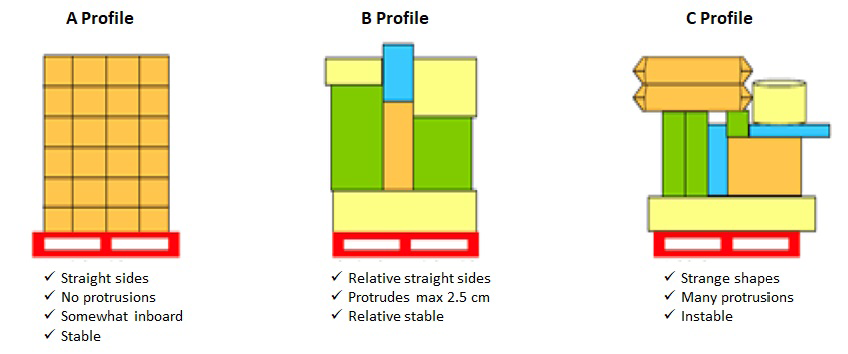

- A turntable that is large enough for your pallet to fit inside the perimeter without protruding corners or trip hazards.

- Sufficient clearance between the edge of the load and the mast of the machine to prevent the operators from being pinched between it and the loads.

Q: How can I tell if the machine is easy to use?

A: Look for:

- Simple film threading technique.

- Simple process to attach film to the load without requiring operators to tuck or tie the film to the pallet.

- Automatic film cut-off option available to eliminate manual film cutting and let operators remove loads from the turntable or wrap zone without getting off the forklift.

- Automation module option available that attaches film to the load, lets the operator start the machine and remove loads from the turntable without ever getting off the forklift.

- Easily adjustable load wrapping choices on the control panel.

- Top and bottom wrap counts displayed on the control panel.

- An operator’s guide is attached to the machine.

- Ability to operate and adjust machine without instruction.

Q: How do I know it’s reliable and durable?

A: Look for:

- A manufacturer with a large customer base, which is a measure of market acceptance

- The key components are lifecycle tested to ensure reliability.

- Little to no preventative maintenance.

- Chains have been replaced with belts wherever possible.

- The turntable support system doesn’t require lubrication or make excessive noise.

- The turntable drive system doesn’t require lubrication or periodic adjustment.

Q: What are the key elements of good support?

A: Screen your prospective purchases against these criteria:

- The manufacturer is available 24 hours a day, seven days a week for support.

- The local distributor has factory trained and certified technicians.

- The warranty for components is five years for turntable machines and three years for straddle machines.

- Operating manuals, videos and parts lists are supplied with the machine.

- Step-by-step troubleshooting and operating guides are supplied with the machine.

- The manufacturer offers extended warranties.

Above all, understand what you’re buying. This means don’t take shortcuts. All machines aren’t equal. Don’t let too-good- to-be-true deals tempt you into buying the wrong thing. Remember, you get what you pay for.

This post was published on March 12, 2015 and updated on October 8, 2019.

March 12, 2015