Choosing to create stable pallet loads may sound obvious, but it is certainly not without obligation. Recently, a company in the United States was ordered to pay $100 million in damages to a warehouse worker who was injured by falling product that was not securely attached to its pallet. The worker was permanently paralyzed in the accident, and the real tragedy is that the accident was preventable.

This historical personal injury award will certainly cause many transport companies in the US to take notice, and start investigating their policies on load stabilization. In Europe, this sort of scrutiny into safe load containment has already begun.

EUMOS legislation

Previously, there were no legal rules for pallet load stabilization in Europe, but this changed with the new legislation from the European Safe Logistics Association (EUMOS) in 2018. This law forces product manufacturers, transporters, and their business customers to look more closely at the safety of transporting products on pallets.

Indeed, within the EU, 25% of all truck accidents are due to trucks in which the load is not properly secured. This results in about 30 fatalities every year. The legislation places heavy demands on the forces the load must withstand and issues high fines for violations. One of the aims of the introduction is to improve road safety.

Moreover, with the introduction of the new regulations, transport damage is no longer only the responsibility of the transporter, but also of the person packing the products. Load stability is therefore not only a means to prevent transport damage, but also to transport lawfully. The introduction of the law has created a joint responsibility for compliance with the rules of this law.

Two key parts of the law are:

- Liability for product damage has moved from carrier to manufacturer. The shipper is responsible for packing products, loading the goods onto the truck, and securing and anchoring the goods.

- The carrier is responsible for approving the loaded and secured products. The carrier should also be in possession of the necessary cargo securing products and the appropriate transport documents to prove that the goods have been correctly loaded and secured.

For every load its own stretch wrapping process

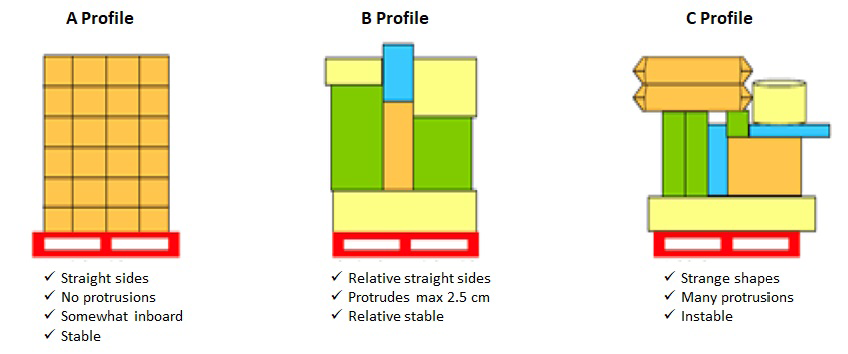

So many products, so many load configurations. Whereas pallets have more similarities than differences, the differences between the types of loads on pallets are endless. However, the ultimate goal of stretch wrapping is the same: to turn multiple loads into a single, safe-to-ship unit. In doing so, we can make a distinction between three load profiles. These profiles are distinguished by the extent to which products protrude over the pallet and fit together.

Even though the load of the different profiles differs in terms of stability, the result of the stretch wrapping process should be the same: high pallet stabilization, allowing the pallet to be transported safely and the products to arrive at the customer damage-free. Film is a light material, but do not underestimate its strength. If the film is wrapped correctly, it can act as a sturdy safety belt.

Which profile do your loads fall under? And are you using the right stretch wrapping pattern for that? If not, this is easy to solve. Look for the optimal wrapping pattern that stabilizes your load.

Remember that whatever stretch wrapping method you use, the basis is always good pallets and correctly constructed loads. The stretch wrapping process does not offer a solution to:

- Loads that are too big or too small for the pallet;

- Broken pallets;

- Poorly stacked loads;

- Loads that are too wide, long, heavy or light.

Protect your work force and avoid expensive, preventable damage claims by not underestimating the power of stable loads.

Want more tips on how to transport goods cost effectively and without damage?

Then download our latest E-Book!

Download eBook