In a word, automation. Most back injuries are a result of lifting, bending over or pulling, especially if those motions are repetitive. If your workers are hand wrapping your loads, they’re doing all three – repetitively.

They bend over to attach the stretch film to the load. Then they pull the film tight and lift the film roll and pull on the film as they wrap the load from the bottom to the top and back down to the bottom again. Or at least as close the bottom as they can comfortably reach. It’s tough work to hand wrap the bottom of a load.

They do this for every load, every day. Performing the very tasks that put them at risk of incurring back injuries. And the risk is high – and expensive, too.

According to the Bureau of Labor Statistics, there were 170,450 work-related back or spinal injuries in 2013, the most recent year they have for data. The BLS doesn’t carry cost data about these injuries, but various sources suggest that the average back injury (sprain/strain) can cost anywhere from $3,000 – $10,000 in direct costs (National Safety Council Statistics). And anywhere from $30,000 to $100,000 in indirect costs. None of that includes the liability involved in an actual lawsuit and settlement or judgment.

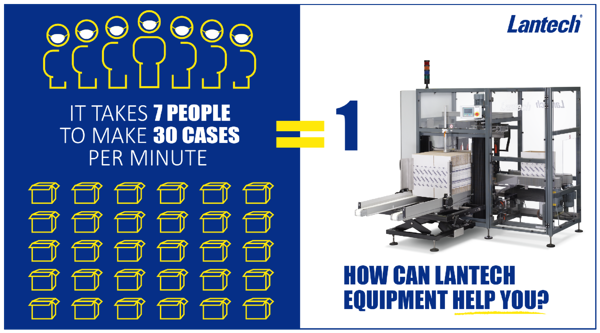

Today’s semi-automatic stretch wrappers automate almost all the tasks that put your people at risk for back injuries. They attach the film, stretch it, and guide the film layers from top to bottom while the turntable spins, finishing the process by cutting the film at the end of the wrap cycle – all automatically. No lifting, bending or pulling required.

There’s more than enough risk to go around. The risk of back injuries from hand wrapping is one that’s easy and worthwhile to eliminate.

This post was published on August 12, 2015 and updated on September 13, 2017.

August 12, 2015