This is a guest post by Adam Cahill from Supply Pointe.

Do you ever find yourself needing to ship an item that simply won’t fit inside a box trailer? Well, sometimes, you just need to think outside the truck. If what you need to ship won’t fit, or you’re facing pick-up and drop-off difficulties, a flatbed trailer might be your solution. Flatbed trailers are ideal for oversized or otherwise unwieldy cargo, and they can be an efficient and affordable way to move a load. However, because the cargo won’t be enclosed, special consideration must be taken to ensure it’s appropriately covered and secured.

Reasons to use an open flatbed truck

Open flatbeds are the champions of oversized shipments. They carry automobiles, heavy machinery, construction equipment and more. You’ve probably even seen an open flatbed truck hauling a prefabricated home or a carnival ride. It makes obvious sense to use an open flatbed to carry these massive items, but many companies cite a variety of other reasons to choose them over box trailers. Loading cargo into a box trailer is a bit like playing the video game Tetris — trying to strategically fit pieces of the shipment together to maximize space, all the while getting increasingly frustrated. Using an open flatbed trailer all but eliminates this concern. People shipping scrap metal, pallets of multiple sizes and shapes, or other unusual materials use open flatbeds to save themselves the headache of trying to fit these things into a box trailer.

Open flatbeds are the champions of oversized shipments. They carry automobiles, heavy machinery, construction equipment and more. You’ve probably even seen an open flatbed truck hauling a prefabricated home or a carnival ride. It makes obvious sense to use an open flatbed to carry these massive items, but many companies cite a variety of other reasons to choose them over box trailers. Loading cargo into a box trailer is a bit like playing the video game Tetris — trying to strategically fit pieces of the shipment together to maximize space, all the while getting increasingly frustrated. Using an open flatbed trailer all but eliminates this concern. People shipping scrap metal, pallets of multiple sizes and shapes, or other unusual materials use open flatbeds to save themselves the headache of trying to fit these things into a box trailer.

Another common reason for the use of the flatbed trailer is the lack of a receiving dock. When a box trailer shipment is prepared, the material is loaded from an indoor dock into the back of the trailer. When the truck arrives at its destination, whether a warehouse or business, the truck is backed into an elevated dock door where the cargo can be easily unloaded directly into the building. If either of those points lacks a dock, an open flatbed truck is necessary so that cargo can be unloaded other ways. Likewise, if the cargo is too difficult to maneuver in and out of a box trailer, using an open flatbed trailer offers more flexibility for loading and unloading. This might be the case when a business is transporting bags of mulch on pallets — it’s just simpler to remove the items quickly from the side of the trailer bed.

When shouldn’t you use an open flatbed trailer? If your cargo is too delicate or you’re shipping many small, loose items or lightweight material that may easily shift or fall off the truck in transit, a flatbed trailer is not a good fit.

Types of flatbed trucks

Flatbed trucks come in a variety of types and should be selected based on what is being moved. Here are a few of the most common.

Regular or stretch flatbed trailers: These traditional-style flatbed trucks can handle weights up to 48,000 pounds, and are often used for steel beams, long pipes, and even massive turbine blades.

Step-deck and drop-deck flatbed trailers: These models include a lower deck designed to accommodate the transportation of tall cargo so that it sits lower to accommodate road clearances. These trailers can carry loads from 40,000 to 45,000 pounds.

Lowboy flatbed trailers: As the name implies, almost the entire bed on this trailer is lowered to allow for greater clearance for tall cargo and easier loading and unloading of vehicles being transported, such as construction vehicles.

Securing and covering your cargo on an open flatbed

Transporting material on an open flatbed offers flexibility, but also presents a challenge. Without the protection of a box trailer, the shipment is at the mercy of the elements. Wind, rain, snow, sun and even animal and human interference all pose risks to the precious product while in transit. Shrink-wrapped cargo is a good candidate for open flatbed shipping, as the heavy-duty plastic surrounding it acts as a protectant. For unwrapped cargo, vinyl, heavy-duty tarps may be used to shield the product; specialty tarps are available to cover and secure lumber, steel, and machinery; shaped tarps are available to fit snugly over large coils; and there are even smoke tarps, which, when secured to the front of a cargo load, protect it from exhaust, dust and road debris kicked up by the truck’s wheels.

Even more important than protecting cargo from the elements, using an open flatbed trailer requires that the material is safely secured. It’s crucial to keep your products from rolling or flying off the flatbed in order to protect them but, mostly, to protect others on the road. The material can be secured with nylon tension straps, high-strength bungee cords or steel chains. Cargo can also be shored up using lumber to prevent it from shifting. The professionals who load open flatbed trucks use specific techniques to tie down items, going through strict safety point inspections before hitting the road. Going through the proper covering, securing and strapping procedures helps ensure your shipment arrives undamaged.

Adam Cahill is the co-founder and co-owner of SUPPLY POINTe, the hub of a unique network of select trucking, freight forwarding, pallet and packaging companies. We connect these companies to offer a wide set of choices and savings for a rapidly growing list of customers in Cincinnati, Ohio, and Charlotte, N.C. Connect with Adam Cahill on LinkedIn, and connect with SUPPLY POINTe on Facebook and Twitter.

You may be interested in these related posts:

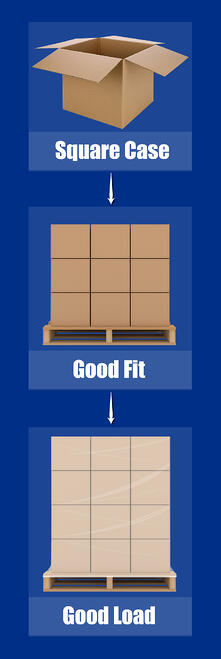

- Are You Shipping Bad Loads?

- Shipping Damage: The Hidden Costs

- Stretch Wrapping and Shipping: A Load’s Untold Story

Image Credit: <dancerinthedark> at Morguefile.com

This post was published on March 9, 2017 and updated on November 28, 2018.

March 9, 2017