In last week’s blog, we point out that even though stretch wrapping has become the standard way to unitize a load for shipment, hardly anyone does it well, which creates a lot of bad loads.

In last week’s blog, we point out that even though stretch wrapping has become the standard way to unitize a load for shipment, hardly anyone does it well, which creates a lot of bad loads.

This epidemic of badly contained loads has huge and hidden costs caused by the waste from unnecessary risk, damage and rework. In our era of economic and environmental challenges, we can’t afford to tolerate these costs.

Containment Force isn’t applied properly to the vast majority of loads that ship today.

As you know, containment force is what holds loads together during shipping and handling. It’s the product of the wrap force applied to the load by the stretch wrapper multiplied by the number of film layers applied in the wrap cycle.

The right amount of containment force should be applied everywhere on the load to the top, middle and bottom. A visual “indicator” that containment force isn’t applied properly is also simple and straightforward: the load has less film in the middle or it looks like an hourglass shape (see picture to the right.)

Instead of having the right amount of containment force at the top, middle and bottom, as a properly wrapped load should, these loads almost always have too much containment force at their tops and bottoms and not enough at their middles. In other words, they have too much containment force where it’s not needed and not enough containment force where it’s needed. If a load’s going to fail, it’s most likely to happen where there’s not enough containment force, which is usually the middle.

The minimum level of containment force on a load determines its success. No matter where the minimum level occurs on a load, when it’s too low, the risk of failure increases.

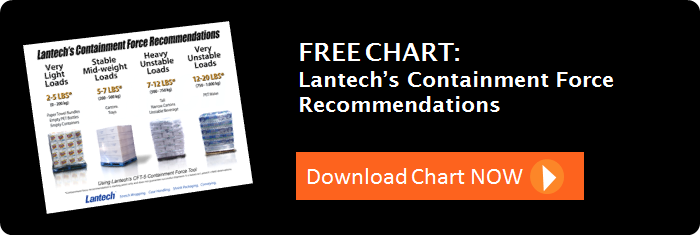

Our Containment Force Recommendation Chart

You need to establish a containment force standard for your loads. If you need help getting started, you can use our Containment Force Recommendation Chart to give you guidelines. You must measure your load’s containment force with a tool in order to know you have the right amount.

The bad news — we see loads that look like our example everywhere. The good news — we know how to fix them.

The obvious fix — redistributing containment force on the load — may not always be quite as easy as it seems. It’s sometimes surprisingly hard to manipulate a 20″ or 30″ wide film web or add or take off film revolutions to precisely dial in the desired level of containment force.

Even though it might require some serious work and testing (and maybe some help from an outside party), it’s well worth the effort to make sure your loads have the right amount of containment force and that it’s properly applied.

Do a quick self-check. Are you practicing these basic containment force guidelines?

1. Know how much containment force your loads need.

2. Make sure that the correct amount of containment force is at the top, middle and bottom of your loads.

3. Have a system in place that ensures you’re really doing what you think you’re doing.

Looking for other ways to improve? Learn 5 action steps that every shipping manager and plant manager should know to make loading docks run faster and safer. Download your FREE copy of The Lean Loading Dock.

Read related article: Are You Shipping Bad Loads?

For more information, you can contact us on our website or call us at (502) 815-9109.

This post was published on January 29, 2015 and updated on November 12, 2019.

January 29, 2015