“We’re building the space shuttle competing against other people who are still flying Spitfires,” Anthony Pratt, Forbes, July 29

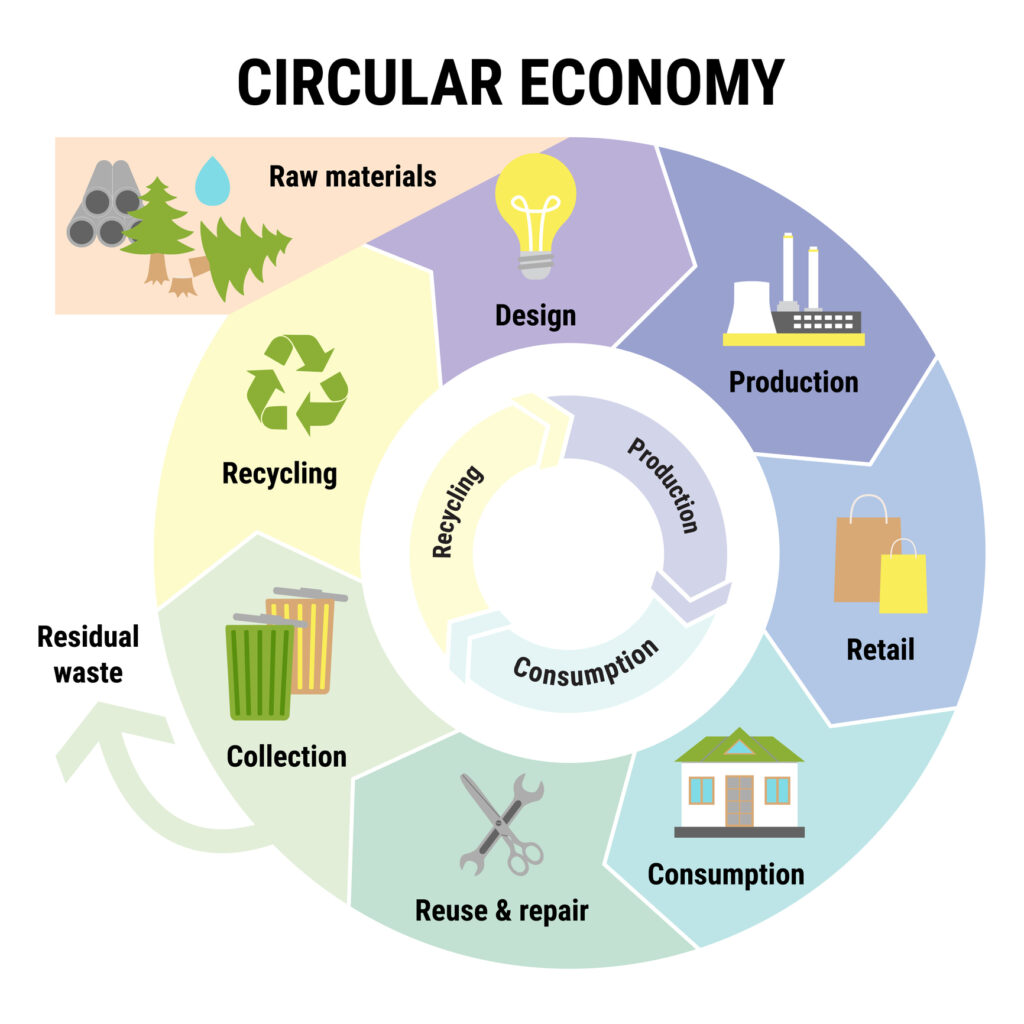

Turning an endless supply of trash into an endless supply of boxes

A recent Forbes article presented an interesting business perspective on the world of paper recycling, sustainability, efficient manufacturing and the impressive business that Australian entrepreneur Anthony Pratt has built in the US.

Recycling isn’t just good business for Pratt industries – it’s a welcome trend in many regards. And for many manufacturers, it’s a key step in helping them meet increasingly stringent sustainability targets set by big box retailers – who in turn are responding to their retail customers’ expectation of greener business practices.

As recycling processes improve so does the quality of the corrugated made from recycled paper content. Soon it may even offer performance parity against virgin corrugated.

But the engineered capability of corrugated boxes (cases, in industry lingo) is often misunderstood and, as a result, critical end of line packaging considerations are overlooked.

Vertical strength

You don’t often see people stack cardboard boxes on their sides. Why? Because, they’re not very strong. The power of corrugated comes from its flutes – and they’re strongest when they’ve vertical. That lets them provide maximum crush resistance. In that way corrugated is a lot like concrete, which has enormous strength to avoid being crushed but much less sheer strength. That’s why you see so much rebar in roadways or concrete beams, for example.

Many products have some headspace or voids when packed in corrugated cases or may be damaged if their cases are crushed. For those products, usually stacked several layers high on pallets for efficient logistics, the ability of the corrugated to provide the stacking strength is critical to avoiding product damage.

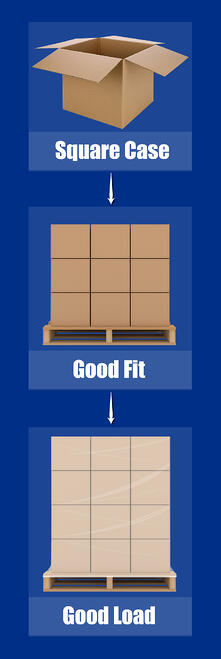

The bottom line is that the sides of the cases, and particularly the corners, provide that power. Sides and corners must be aligned to create a strong column to enable cases to protect their contents from the rigors of shipment.

Square, straight and aligned

Corrugated provides the power of protection for products during shipment, warehousing and handling. But it’s not a given. In fact, the details of end of line packaging operations actually play a large role in whether the corrugated actually performs up to its engineered capability. Here’s a quick look at two important considerations:

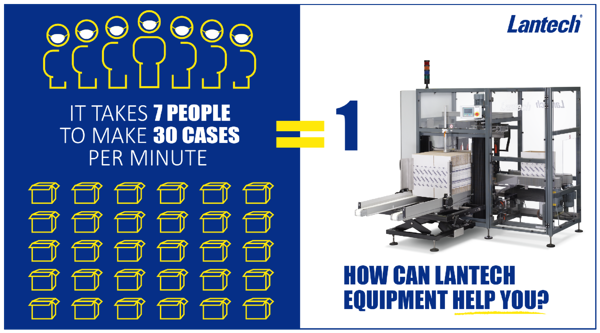

- The power of the case is generated by its flutes. And they must be vertical to maximize their strength. Sounds simple, but it’s actually remarkably uncommon! Surprised? Here’s the thing. In order for the sides of a case to be vertical the minor and major flaps on both the top and the bottom must be closed consistently and squarely. As a rule of thumb, that simply doesn’t happen when cases are manually erected and closed, particularly when they sealed with tape dispensers. Or when they’re pushed through carton sealing stations after manual erection and loading. In fact there are actually 5 steps to producing square cases as described in this article. And one consideration that’s sometimes overlooked is the ability of case handling equipment to automatically handle recycled corrugated cases. Don’t assume that it will!

- Once the cases are square and the sides are vertical, the next step is to ensure that the column stacks are properly aligned and remain that way during shipment. “Remain that way” is the toughest challenge here – after all between the forklift rodeo and long haul routes in the back of trailers, you can imagine how cases are prone to get “rearranged.” The solution is proper stretch wrapping, and appropriate containment force. That’s easier said than done. Because cases don’t have a lot of strength on their sides, you can’t wrap too tightly, or you’ll crush them and damage the contents. The answer lies in wrapping properly for the load – and that requires training and familiarity for operators. Most stretch wrapper marketing makes it sound like all machines do the same thing – lay stretch film along the side of a pallet. But a pallet wrapper needs to be able to optimized for a load to properly contain it with the least amount of stretch film.

Square cases and proper stretch wrapping are both important elements of sustainability. Managing them is critical as companies continue to lightweight their corrugated and use more recycled materials.

End of line packaging and sustainability

Reducing virgin corrugated and stretch film are both important steps toward sustainability and cost reduction. Both can make significant environmental and economic contributions.

But the greatest win comes through reducing damage. If you prepare a load with less packaging material but the product is damaged in shipment then not only are the packaging materials (both primary and secondary) wasted but all the material and energy that went into manufacturing the product, transporting it and disposing of it is wasted as well.

So keep in mind that sustainability and cost reduction measures can’t be allowed to compromise safe shipment and delivery!

Want to take a look at how to select the right end of line packaging solution for your operation? Start with our free Pallet Wrapper Buying Guide.

image – Jamel Toppin for Forbes

This post was published on August 10, 2015 and updated on August 10, 2015.

August 10, 2015