Every manufacturer or logistics provider knows the challenge: what is the importance of a box? It’s all about protecting the contents, right? And even though product packaging costs a lot of time and money, the expenditure is necessary. Despite those costs, 2% of all products still get damaged during transport. With the current scarcity of materials and very long delivery times, nobody can really afford any amount of damaged product.

Products must arrive at their destination in perfect condition to avoid additional return transport costs, and so that it doesn’t eventually end up as waste in a landfill. To help mitigate transport damage and save you money in the long run, we explain which type of case erector or case sealer is right for you in this blog.

When it comes to erecting cases, there are basically two options; Either the operators erect cases by hand, or you get a machine to do it. Erecting cases manually is tedious work and is very slow compared to a machine. In addition, in today’s tight labor market, employees are not always easy to find.

Plus, the ability to manually erect cases perfectly square is questionable. As capacity goes up and large volumes are produced and/or transported, the need for automation will increase.

But where is the tipping point? In general, if you need three or more boxes per minute, it is best to switch from hand-erecting to a case erecting machine. A case erector automatically erects flat cases and seals the bottom of each case. Although a case erector requires a one-time, larger investment up front, your ROI is quickly gained. The reduction in product damage incurred during transit alone is worth the cost. But also, the productivity of your packaging process increases and the cost-per-case being erected decreases.

So, if you need more than three cases per minute then a machine is a good solution. But how do you decide which type of machine you need?

To find out, ask yourself these six questions:

1. First, what do you need the machine to do? Do you need the machine to just erect the cases, or do you need them sealed at the bottom?

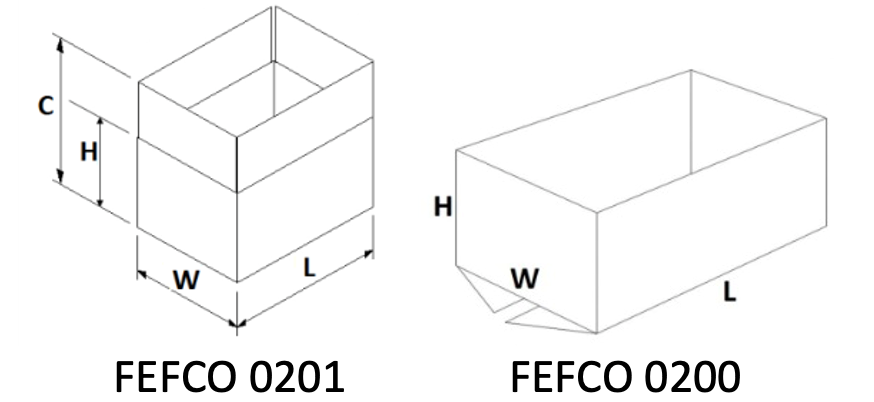

2. The next question is, what type of case do you use? For example, a FEFCO 0201 or a FEFCO 0200?

3. Now, think about capacity. How many cases need to be erected per minute? (Some machines have a range up to 30 boxes per minute).

4. What kind of seal is used, or required? Often the choice is between Tape or Hot Melt Glue.

5. Will the machine be a part of your packaging line, or does it stand alone? This is very important!

6. Finally, in which industry is the machine being used? For example, there are very different requirements in the food sector than there are in the e-commerce industry.

Finding it hard to choose which case erector and/or carton sealer you should purchase? Use our configurator to find out which machine is the ideal type for your business and find the perfect match for your packaging process!

Finding it hard to choose which case handling solution you should purchase?

Use our configurator to find which machine is ideal for your packaging process.