When former Intel CEO Andy Grove realized Intel could no longer compete in the memory chip market, he took a big  risk. He shifted the company’s focus to microprocessors. Grove would ultimately build Intel in a $26 billion company.

risk. He shifted the company’s focus to microprocessors. Grove would ultimately build Intel in a $26 billion company.

Grove is often quoted saying this: “Business success contains the seeds of its own destruction. Success breeds complacency. Complacency breeds failure. Only the paranoid survive.”

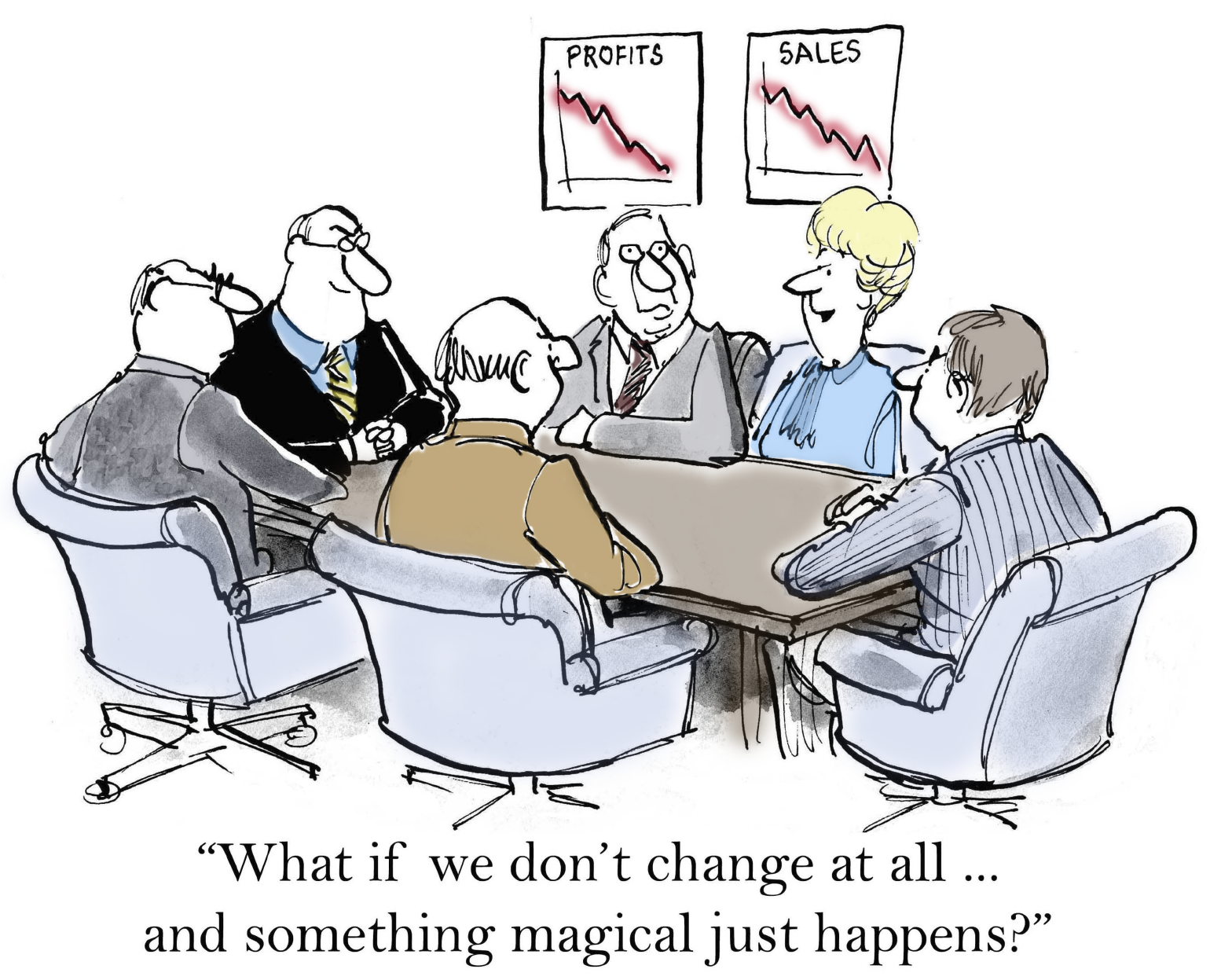

When people form habits or become complacent with certain behaviors, they’re unlikely to change – for better or worse. And when businesses don’t take risks, they close the door to potential success and survival.

It’s important to keep an open mind to adopting new ways to improve your current situation. Maybe that’s expanding your product line or automating a manufacturing process.

Change is hard, and it can be unpopular with management and employees. But sometimes it’s a good thing and will help your company increase its revenue stream. And eventually, people will come to accept it.

One way you can make a positive (and relatively easy) difference in your company is to change the way you stretch wrap. For example, if you’re hand wrapping, changing to a semi-automatic stretch wrapper can improve productivity, reduce product damage and save money.

By swapping from hand wrapping or changing out an old machine for a new one you can wrap better loads and immediately stop wasting film and labor. Stretch wrappers with increased automation, like a cut and clamp unit can help the average company wrapping 50 loads per day recover about $50,000 in wasted labor over five years and help create safe-to-ship loads.

You can also rethink the way you weigh loads for shipment. Some modern stretch wrappers combine activities like weighing and wrapping. The built-in scale can save the average company wrapping 50 loads per day up to $15,000 in labor over five years.

Andy Grove was right – only the paranoid survive. Don’t settle with what you think works just OK. Question what you’re doing, and continue to make it better.

This post was published on April 20, 2016 and updated on May 20, 2020.

April 20, 2016