Safety

Lantech equipment was designed with safety in mind, from the enclosed design of the mast, turntable & film delivery system of our stretch wrappers to the ergonomic magazine loading design and safety curtains and shields on our case & tray equipment. There are a variety of safety features that come standard on all Lantech packaging machines to ensure your people are always protected.

Easy to use

“I don’t have time to train my people.” Lantech stretch wrappers’ simplistic design makes it easy to set up wrap patterns, load film correctly every time, and can ensure the quality of every load with intelligent software. The simplistic design of our case & tray equipment makes changeovers quick and creates square cases every time. Lantech packaging equipment also requires no routine maintenance.

Package Performance

There is no match to Lantech technology. Our solution-driven equipment, record of patents, and automated packaging knowledge make us the leaders of the industry for over 50 years. The design and features of both our stretch wrapping and case & tray handling equipment were developed to maximize productivity and performance while delivering safe-to-ship loads every time.

Uptime

Don’t go down because of inadequate industrial packaging solutions. Wrap a safe-to-ship load every time, no matter the speed and throughput required or the shape and weight of the load. Likewise, our unique case & tray equipment design overcomes case variations and keeps jams at bay so your line can keep moving.

24/7 Support

Lantech support and service is here when you need us! Our best-in-class warranty and availability of technical support is second to none. Lantech’s knowledgeable team of technicians offers support 24/7 to get your machine back up and running fast. We support all of the stretch wrapping machinery and case & tray machines we have ever built.

Healthcare

Lantech machines beat them all with reliability, simplicity, and cost."

By adding the Lantech case erectors and sealers to eleven packaging lines, the company has reduced their operating costs by an estimated $750,000 per year. Introducing automation also eliminated the ergonomic risks caused by the repetitive motions involved in the hand-erecting process.

Food & Beverage

Lantech was always there, responding in a timely manner to our requests and helping achieve our goals."

A food and beverage company, wrapping over 350,000 loads per year, reduced their film consumption by 25% with Lantech’s Metered Film Delivery System. This reduction in film resulted in a savings of $54,750 annually thanks to a Lantech wrapping system!

Warehouse Logistics

The other employees previously needed for hand wrapping were reallocated to alternate areas of the operation."

Previously, multiple employees were used to hand wrap their skids. The improved productivity of the S300 stretch wrapper has enabled the Provider to now use a single employee to manage the wrapping station.

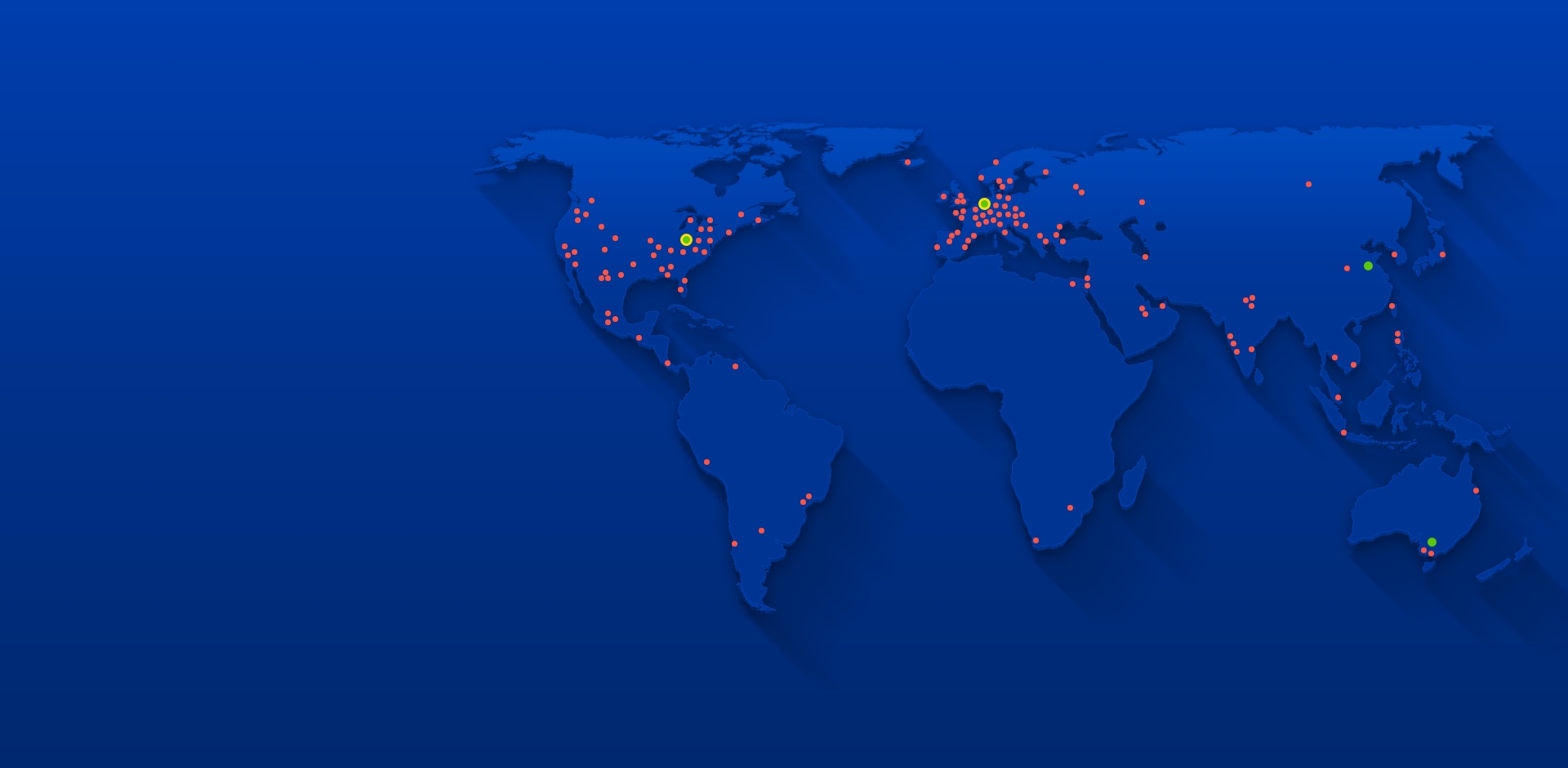

50+ years of trusted value built just for you

We live, breathe, and study our customers’ environments 24 hours a day, 7 days a week, and 365 days a year. We know firsthand the challenges they face. With unwavering passion and dedication to R&D advancements, we re-invent our automated packaging systems with new industry-leading features and performance-enhancing technology to solve our customers’ real-world problems while reducing or eliminating transport damage and waste globally.