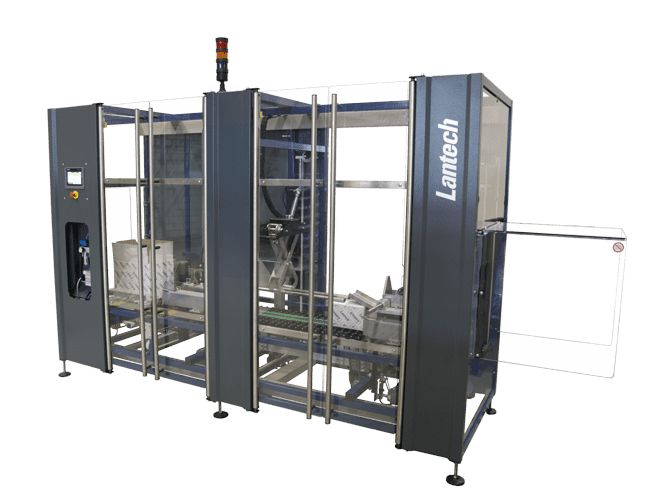

Why Lantech Case, Tray & Lid Handling Equipment

Lantech Machines Are Built To Last.

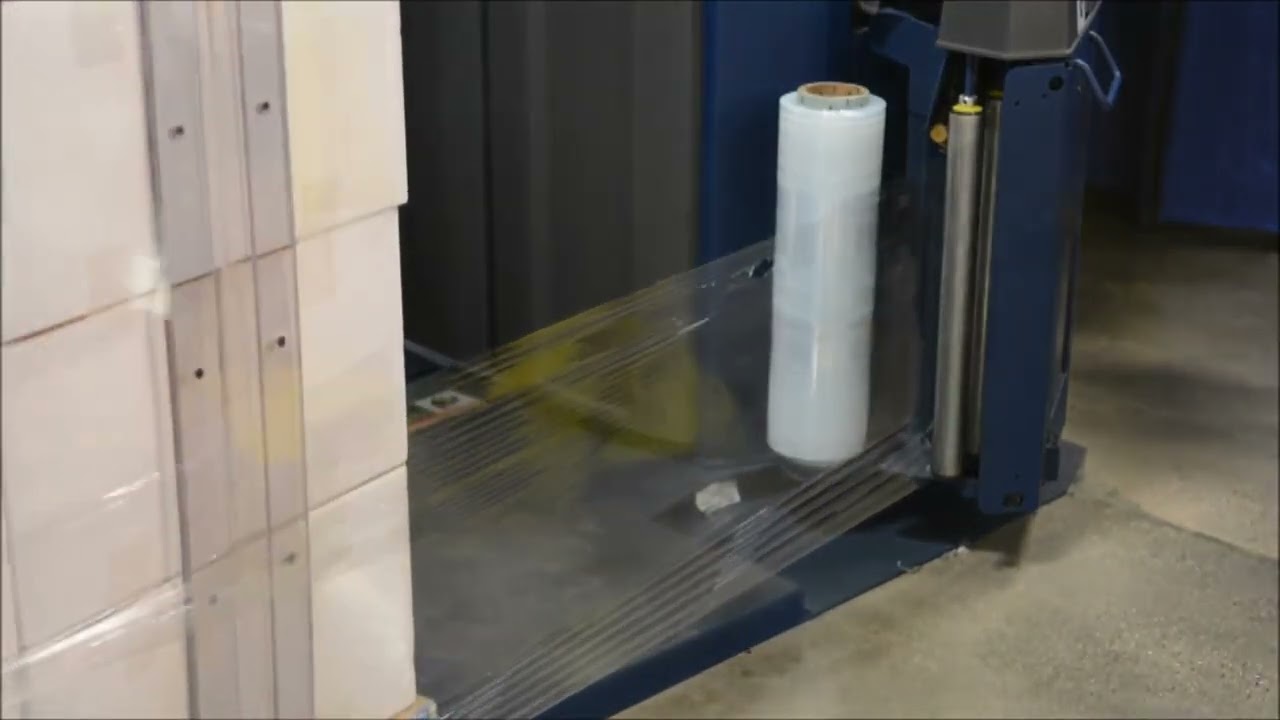

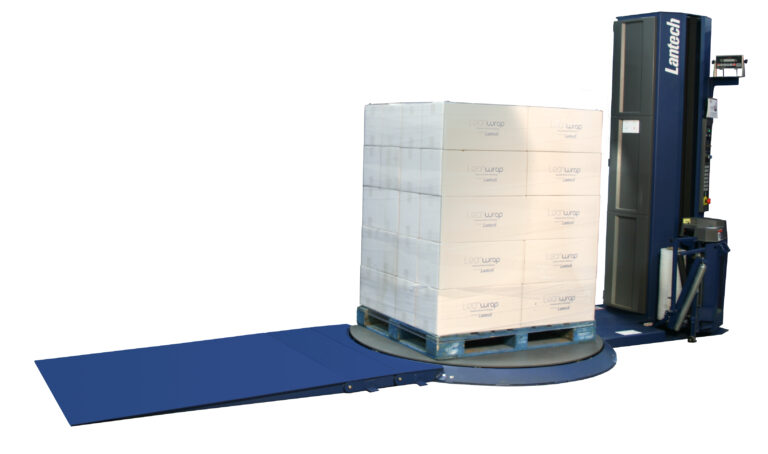

Our machines are solid, stable, strong and reliable and are designed to deliver the highest level of performance and productivity to help our customers achieve their shipping objectives.

Lantech Advantages

Our Case, Tray & Lid handling equipment is easy to use, safe and reliable.

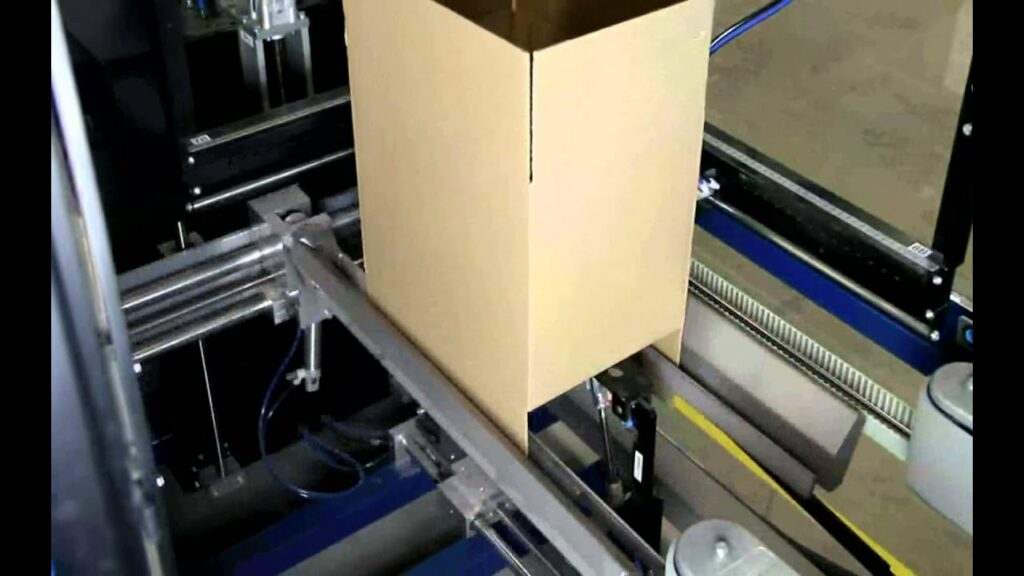

Square Cases, No Jams!

Square cases stack, pack and ship better!

Why Square Cases are Important

A square case is one with 90-degree angles on all corners, sides are vertical, and when the tops and bottoms are sealed, they are flat and perfectly horizontal. This seems easy to achieve, but the devil is in the details. Without these characteristics, a case is un-square and can contribute to shipping damage – which means unhappy customers, lost profits, and rework – and downstream jams.

When stacked on a pallet, formed cases that are un-square lose 30 percent of their stacking strength. This reduction of support leads to crushed cases and off-center loads causing potential damage to the contents and puts the load at a great risk of falling apart during transit. In addition, un-square cases can cause production line jams downstream, especially when using case packers and sealers.

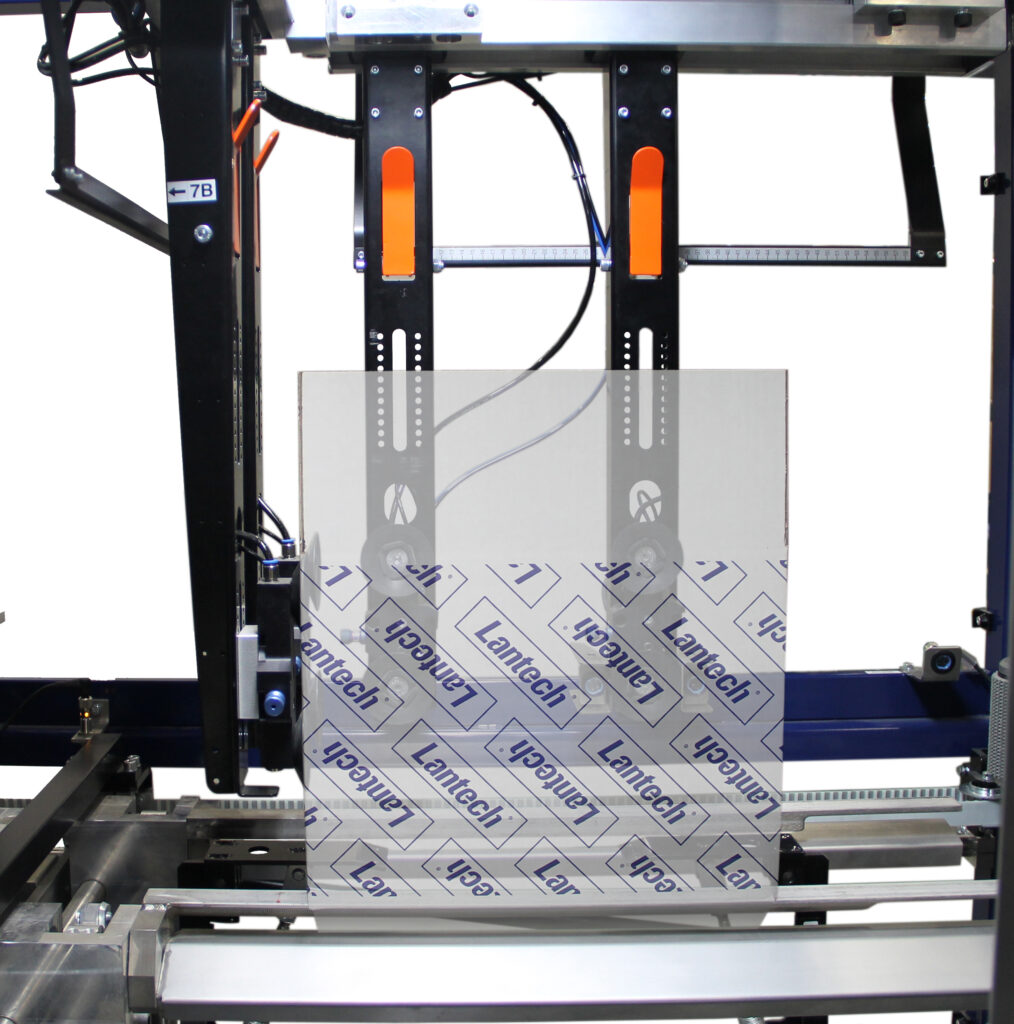

When cases are perfectly square with 90-degree angles products can fit better inside and they can be stacked and wrapped properly for greater shipping success. Lantech achieves square cases, every time with our unique pick-up frame that pulls the blank square and continues control through flap folding and sealing.

Why Lantech Can Claim "Square Cases, No Jams!" Ability to Overcome Common Problems

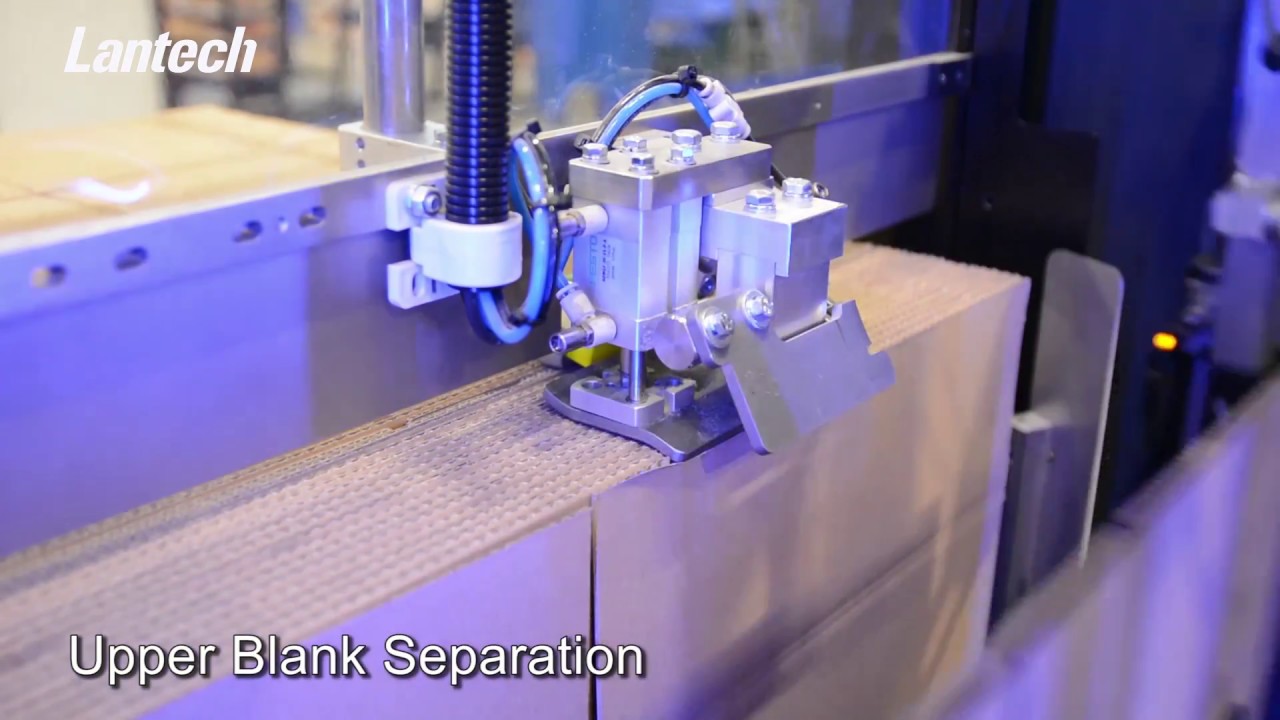

Nearly all case erector jams can be traced directly to 4 primary problems; blanks are not fed correctly into the magazine, irregularities in the blank from the carton supplier, the mechanical forces of opening the cases and folding the flaps, and transport the formed case through the machine.

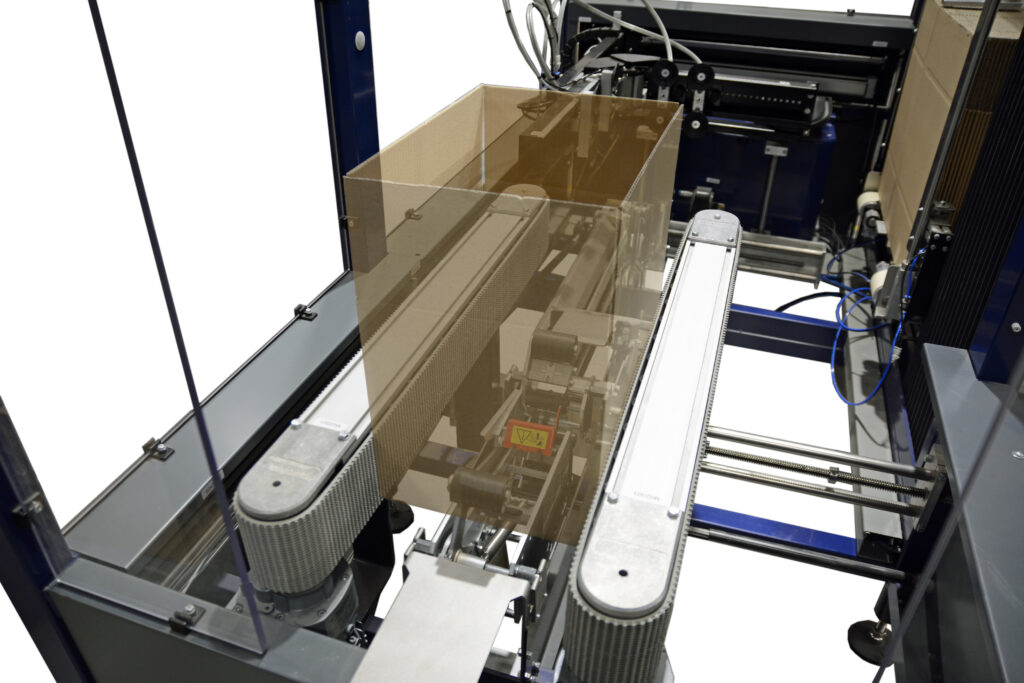

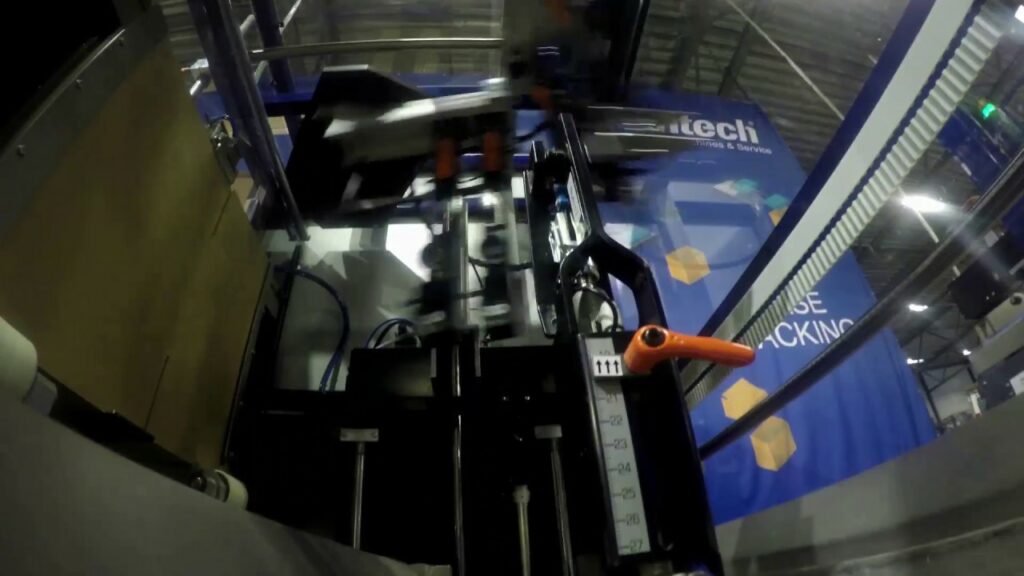

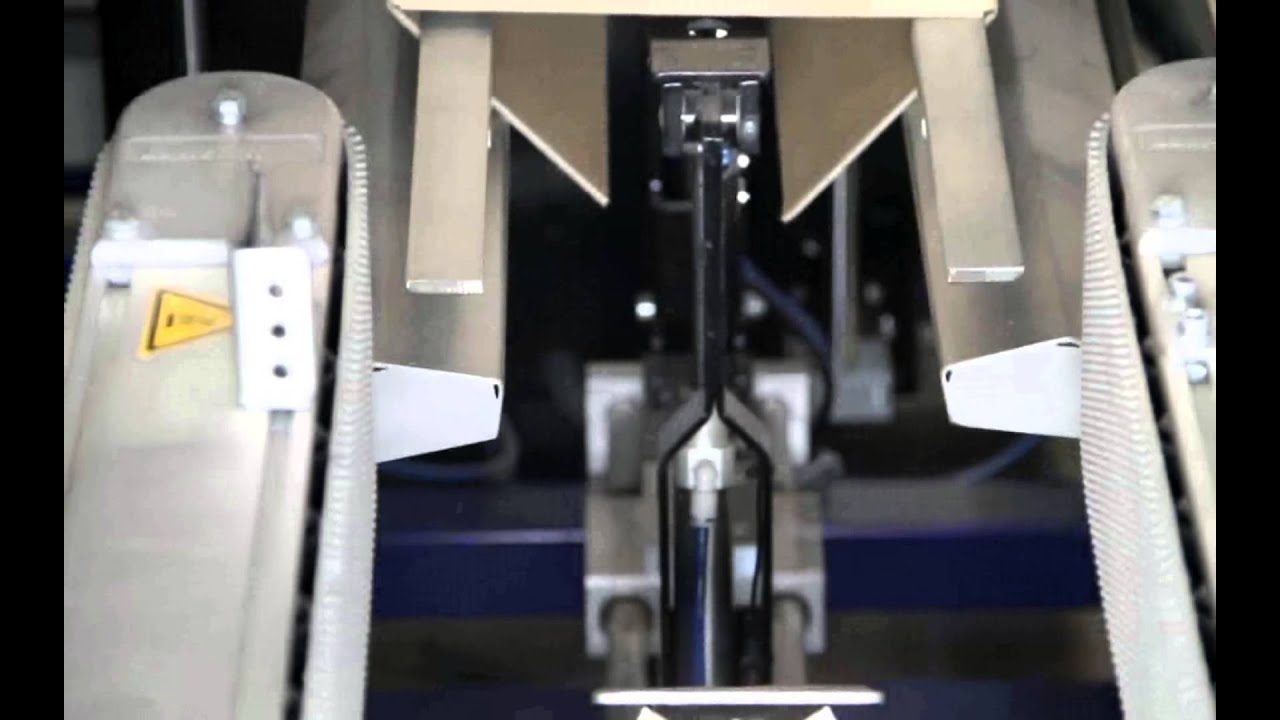

Lantech’s case, tray and lid equipment provide 100% precise control through the entire forming process. The proactive system where blanks are pulled into their next position versus being forced ensures the case performs as designed and is produced with maximum efficiency.

Because of our unique Total Control System, Lantech is the only manufacturer who can honestly deliver square cases without jams.

Our Total Control System:

- Minimizes Downtime

Quick changeover between different case sizes, zero machine jams, reliable and easy to use. - Reduces Waste

Overcomes case variations and poor construction of blanks so all cases can be used. - Forms Square Cases

Forms perfectly square cases so they pack, stack and protect products better.