You’ve done your market research, created a product that your customers love, and implemented world-class production with top-notch quality. Now there is only one thing left to do – pack the boxes and ship the product. What are my options for case erecting and sealing? Should we just manually erect and seal the boxes, or should we completely automate the process?

The reality is that case packing, and the integration of end of line packaging equipment, falls on a continuum from fully manual to fully automated. It’s important to know what all of your options are so you can choose the best solutions for your specific situation.

If you’ve been considering a case erector for your production line, here are five benefits a case erector can offer your company.

1. Increases productivity

The average worker erects three boxes every minute. A basic case erector can produce 10 boxes per minute. That’s a productivity increase of 233%. Faster machines increase productivity even more.

To make 2,500 cases, it takes almost 14 hours of time to erect them by hand. With a case erector, your time is reduced to only four hours. What could you do with ten extra hours?

2. Reduces operational costs

Similarly, if you find you’re adding workers to the packing area because they can’t all keep up, you may discover that by having boxes being made quickly and easily, your packers work much more efficiently. That means you can reduce overtime, or reassign the labor pool, so the extra people can work elsewhere.

3. Reduce repetitive strain and the possibility of injury

Anyone who performs the same task over and over again knows the pain of repetitive strain injury. Also, multiple cuts and lacerations can result from contact with the edges of the cardboard or exposure to the blade in a hand-held tape dispenser. Using a case erector greatly reduces the risk of workers injuring themselves, or suffering repetitive strain injury.

4. Reduces inventory

If you’ve ever had your workers erect dozens or even hundreds of boxes in anticipation of a large shipment, you know the headaches of trying to find space for all of those empty boxes. You’re basically paying to store a whole lot of empty! Each box takes up valuable floor space if you have to regularly pre-assemble boxes just to keep up with a large product flow.

Since you know that pre-ordering raw materials or pre-erected finished products wastes space, you’ll understand how pre-erecting boxes does the same thing.

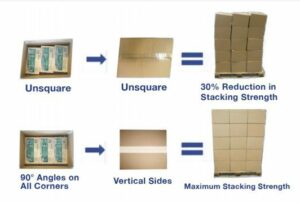

5. Reduces shipping damages

In a previous blog post on case erectors, we talked about how hand erecting cases can often lead to unsquared boxes, which are weaker when stacked on a pallet. But square boxes can withstand heavier weights, which means they are less prone to shipping damage. Using a case erector can help ensure products arrive intact and undamaged.

The main objections to case erectors are that they jam easily and cause downtime. When erecting a high number of cases daily in a production line, this can be a major frustration. There are four primary reasons case erectors jam:

- Blanks are not fed correctly into the magazine.

- Irregularities in the blank from the carton supplier.

- The mechanical forces of opening the case and folding the flaps.

- Transporting the formed case through the machine.

- Find out how to can overcome these problems and what to look for in a case erector that will not only erect perfectly square cases, but will also not jam.

A case erector might seem like an unnecessary extravagance. But when you look at the extra cost and time lost in unproductive work, overtime and injury, you begin to see the benefit a case erector can bring to your company.