As pallet loads of products make their way to their destinations they go through a lot of stress. All of those pot holes, curbs and sudden stops have the potential to cause loads to spill in a trailer. This can be a major cause of damage you don’t want to ignore. Here are two things you can do to keep pallet loads from failing during shipment.

1. Unitize loads properly.

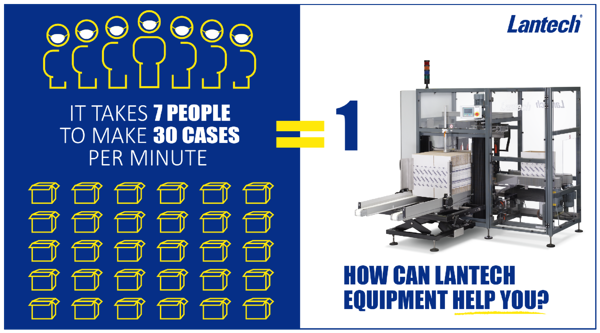

This is your first layer of defense. Today, stretch wrapping is the most popular way to unitize loads. The better you wrap a load, the better chance it has to arrive damage free. And using a machine will give you the best results.

However, it’s hard to tell when you’re wrapping effectively. Following these rules will help you create a load that has the best chance of survival.

- Apply the required amount of containment force. Containment force is the squeezing pressure stretch film exerts on the load. If your load doesn’t have enough containment force, it has an unnecessary risk of failing.

- Lock the load to the pallet with a film cable. Film that’s rolled into a cable and applied just below the top deck boards of a pallet will help prevent loads from sliding off their pallet. The placement of the cable keeps forks from puncturing the film as a forklift or pallet jack picks up the load.

- Make sure there are no long or dragging film tails. Film tails have a tendency to get caught in downstream equipment like conveyors or automatic storage and retrieval systems, causing jams or the film to rip or pull products off the pallet.

2. Load trailers strategically.

It’s important that you use the right pattern to make unloading easy and protect products from possible damage. Base your loading pattern on the weight and height of the pallets.

- Balance the weight. It’s important to distribute the weight evenly to counteract the movement of the trailer.

- Minimize the difference in height between adjacent loads. Placing loads of similar height next to each other creates a natural wall, protecting the loads from completely collapsing.

- Fill large empty spaces. If there are large gaps in your loading pattern, fill the voids with airbags or other dunnage.

Companies around the world lose billions of dollars due to ineffectively stretched wrapped loads failing during shipment. There is no guarantee loads will arrive to their destinations unharmed, but effective stretch wrapping and being smart about how you load a trailer can reduce the risk of your loads failing and being damaged.

The main predictor of your load arriving at its destination undamaged is having enough containment force. If you are unsure how much containment force your load needs, download our Containment Force Recommendation Chart.

This post was published on June 3, 2016 and updated on August 8, 2017.

June 3, 2016