If you’ve been considering a case erector for your production line, wonder no more.

Here are five benefits a case erector can offer your company.

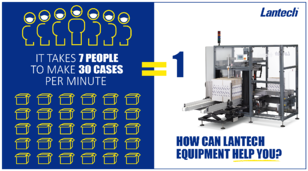

1. Increases productivity

The average worker erects three boxes every minute. A basic case erector can produce 10 boxes per minute. That’s a productivity increase of 233%. Faster machines increase productivity even more.

To make 2,500 cases, it takes almost 14 hours of time to erect them by hand. With a case erector, your time is reduced to only four hours. What could you do with ten extra hours?

2. Reduces staff hours

Similarly, if you find you’re adding workers to the packing area because they can’t all keep up, you may discover that by having boxes being made quickly and easily, your packers work much more efficiently. That means you can reduce the number of people working in the area, reduce overtime, or reassign the labor pool, so the extra people can work elsewhere.

3. Reduce repetitive strain and the possibility of injury

Anyone who performs the same task over and over again knows the pain of repetitive strain injury. And, believe it or not, you can get a large and nasty paper cut from a cardboard box (No, really! A brand new edge is like a dull knife.). Using a case erector greatly reduces the risk of workers injuring themselves, or suffering repetitive strain injury.

4. Reduces inventory

If you’ve ever had your workers erect dozens or hundreds of boxes in anticipation of a large shipment, you know the headaches of trying to find space for all of those empty boxes. You’re basically paying to store a whole lot of empty! Each box takes up floor, storage, and even walk space, if you have to regularly pre-assemble boxes just to keep up with a large product flow.

We’ve talked in the past about the inventory muda (waste). Since you know that pre-ordering raw materials or pre-erect finished products wastes space, you’ll understand how pre-erecting boxes does the same thing.

5. Reduces shipping damages

In a previous blog post on case erectors, we talked about how hand erecting cases can often lead to unsquare boxes, which are weaker when stacked on a pallet. But square boxes can withstand heavier weights, which means they are less prone to shipping damage. Using a case erector can help ensure products arrive intact and undamaged.

A case erector might seem like an unnecessary extravagance. But when you look at the extra cost and time lost in unproductive work, overtime, and injury, you begin to see the benefit a case erector can bring to your company. For more information on how a case erector can improve productivity and reduce costs, visit our case erector overview page.

Click here to read related blog posts: Square Cases 101: Why You Need Them

This post was published on September 20, 2017 and updated on August 4, 2020.

September 20, 2017