Companies spend billions of dollars each year on non-fatal workplace injuries. The pain and suffering workers endure is just as devastating. The Bureau of Labor and Statistics reported a total recordable rate of 5.5 injuries per 100 full-time workers in the warehousing and storage subsector. That means out of the 705,000 workers, about 39,000 of them were injured in 2012.

Here are four things you can do now to help reduce workplace injuries.

1. Improve ergonomics.

The National Institute of Occupational Safety and Health (NIOSH) estimates that warehouse workers are eight times more likely to suffer back injuries than other workers.

- Provide training on proper lifting and bending techniques to help minimize the impact on worker’s bodies.

-

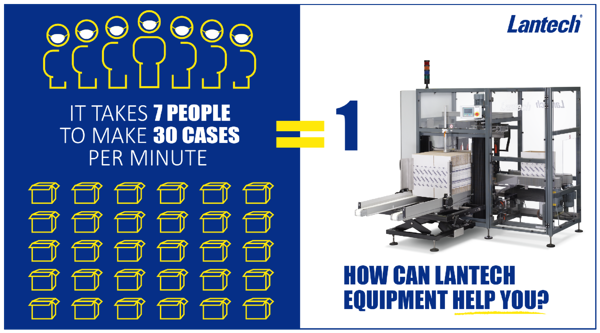

Automate rote work. For example, instead of wrapping pallets by hand, use a stretch wrapping machine. This reduces the time workers spend in compromising positions. To learn more about stretch wrappers visit www.Lantech.com

2. Keep floors clean and aisles organized.

According to Liberty Mutual, injuries resulting from falls cost U.S. businesses $15.2 billion in 2012.

- Clean spills immediately and sweep often. Wet floors or those peppered with debris can cause slips and trips.

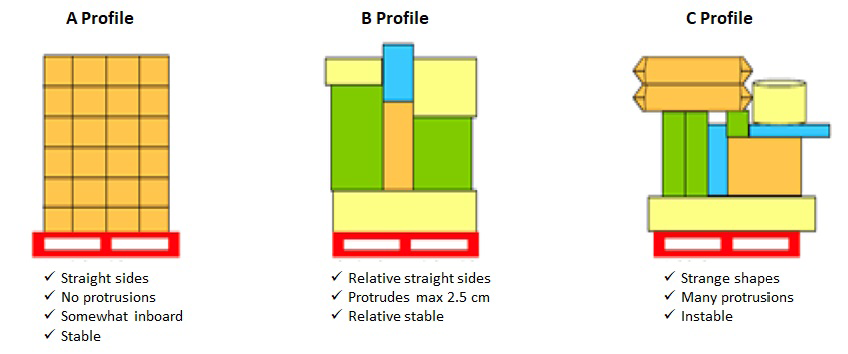

- Keep aisles well organized. Poorly stacked products can easily topple over, striking someone underneath. Protruding objects on the floor can be tripping hazards as well.

3. Follow forklift safety practices.

Occupation Safety and Health Administration (OSHA) estimates that there are 110,000 forklift accidents each year and estimates that 70 percent could have been avoided. Common reasons for injuries due to forklifts include high pedestrian traffic, blind spots, narrow aisles and forklifts overturning.

- Paint traffic lanes for trucks and pedestrians. Clear markings on the floor keep traffic from merging together.

- Install lights and mirrors throughout the facility to increase visibility in dim lit areas and blind corners.

- Provide wide enough aisles for trucks to easily maneuver through. This will help prevent trucks from overturning or striking objects or people.

- For more information about powered industrial truck safety practices visit www.osha.gov/SLTC/etools/pit/index.html.

4. Assemble a safety team.

Awareness and training are key. Your safety team should be a representative sample of everyone who works in the facility from the floor to the upper leadership. The team’s job is to:

- Train new employees.

- Audit your operation on a regular basis.

- Perform forklift safety checks.

- Make sure safety practices are being followed.

Why take risks when small, inexpensive changes can make a big difference? Use these tips to lay the foundation of a well-organized facility that cares about its people. Remember, it’s everyone’s responsibility to create a safe working environment.

Wondering what other factors to consider? Download our free eBook – Machine Stretch Wrapping: Driving Economical, Efficient & Ergonomic Loading Dock Operations.

This post was published on March 18, 2015 and updated on October 8, 2019.

March 18, 2015