When you ship loads internationally – whether by truck, rail, ship, or air – the extremely long distances and harsh conditions can wreak havoc on your loads. The conditions internationally shipped pallet undergo can lead to film punctures, tears, breaks, and, ultimately, damage to your goods. And having an internationally shipped load refused because of damage, even simply losing part of the load to damage, can mean a big hit.

So, while we can’t guarantee that a load will never be damaged, we’ve put together a list of general guidelines that will help you when preparing a pallet for shipping internationally and ultimately minimize the chances of damage.

1. Keep your products dry

According to the Allianz Risk Consulting bulletin about condensation, moisture can cause metal shipping containers to arrive rusted, oxidized, or corroded. Moisture in the shipping containers can cause corrugated cases inside to weaken, fall apart and even become coated with black mold.

You can’t keep the moisture from creeping into containers, but you can take steps to protect your pallet loads. Consider taking the extra step to apply moisture barrier protection, like using top sheets to cover your loads. If you can, you may also want to install adhesive plastic strips onto the walls of your shipping containers to seal any openings (Allianz Risk Consulting).

2. Make sure your loads are stretch wrapped effectively

The biggest element of international shipping that you have control over is your pallet load itself. The best way to reduce the chance of damage then is to do everything in your power to ensure that your pallet loads are wrapped correctly. A key element of properly wrapping a pallet, and reducing the risk of damage, is to make sure they have enough containment force. This is the squeezing pressure the film puts on the load.

Containment force is measured in pounds (or kilograms) using a special tool. For information on how to measure containment force, click here.

Different loads require different amounts of containment force. Knowing how much your load requires is based on experience. If what you’re doing is working – no damage during transit – use that number as your benchmark. If you don’t know how much containment force you need, start by downloading a copy of our containment force guidelines.

Also, you’ll want to make sure your load is bonded to the pallet, to keep it from sliding off. Some people think applying the film all the way down to the bottom of the pallet will do the job. But punctures in the film (caused by the forks on a forklift or pallet jack) can jeopardize the load to pallet bond.

Stretch wrappers with good load to pallet bonding devices will secure a load to its pallet. These devices roll the bottom 3-5 inches of film into a tight cable and place it just below the top board of the pallet. By placing the film here, you can reduce the risk of fork punctures and keep the load in place.

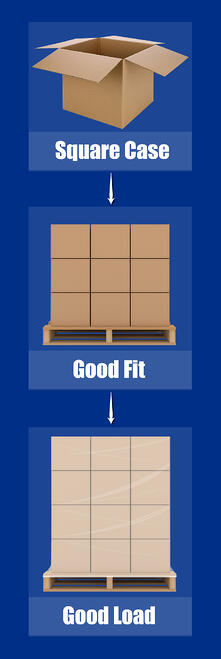

3. Fit your loads within their pallets.

Don’t forget about the importance of using the right pallet size. You want to be sure that you are using the correct size of pallet for the load you are shipping.

Make sure the load sits within the pallet’s perimeter. If the load is too far inside the perimeter (more than about 2 inches), you won’t be able to properly secure it to the pallet. And if the load overhangs the edges of the pallet, the load can hit other loads causing damage.

Also, keep in mind that some countries may require you to heat-treat wooden pallets in order to eliminate possible pests or diseases in the wood. We recently published an article that takes a deep dive specifically into how to prepare your pallet for international shipment.

You may be interested in these other posts:

- Film Cable vs. Film Rope – Load Securing with a Stretch Wrapper

- Preparing Pallet Loads for International Shipment

This post was published on December 20, 2016 and updated on March 13, 2019.

December 20, 2016