Lantech SL Automatic Stretch Wrappers

The SL Automatic Stretch Wrapper comes equipped with Lantech’s patented LeanWrap® features which are designed to maximize productivity and performance:

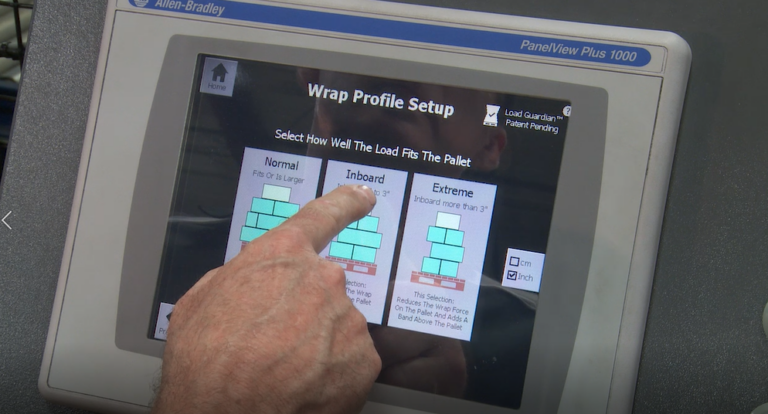

- Load Guardian®: Creates, maintains and delivers safe-to-ship loads every time.

- Pallet Grip®: Locks your load to the pallet.

- Metered Film Delivery® System: The next generation of film delivery systems wraps your loads tighter with less film.

- Load Seeking Clamp® 4.0: Reduces film breaks.

- PLd safety rating for electrical components; PLc safety rating for pneumatics.

Less Waste, Safer Loads!

Specifications

Performance

Production Speed

Up to 50 Loads/Hr

Maximum Load Size

1372 mm L x 1219 mm W x 2032 mm H

(54" L x 48" W x 80" H)

Minimum Load Size

914 mm L x 914 mm W x 686 mm H

(36" L x 36" W x 27" H)

Maximum Load Weight

Conveyor Capacity

Performance Features

Pallet Grip®

Standard

Load Guardian

Standard

Standard Pre-Stretch

225% (100-300% Available)

Film Capacity

254 mm Diameter, 508 mm Width

(10"D x 20" W)

Film Delivery System

Metered Film Delivery® System

Automation Unit - Film Clamp

Load Seeking Clamp® 4.0

Load Handling

Wrap Arm Drive

VFD Motor Control

Wrap Arm Speed

15 RPM

Weight and Size

Approx. Shipping Weight

1950 kg (4300 lbs)

Service Requirements

Pneumatic

6 Bar, 3-5 cfm @ 80 Psi, Clean, Dry Air

Dedicated Electric Service Req. US

460V-30 Amp-60Hz, 3 Phase Wye w/Ground

Dedicated Electric Service Req. EU

3L-PE-400V-50Hz (No Neutral)

Enclosure

NEMA 12, UL

Control

PLC with HMI

Warranty

Warranty Duration

3 Years, Unlimited Cycles

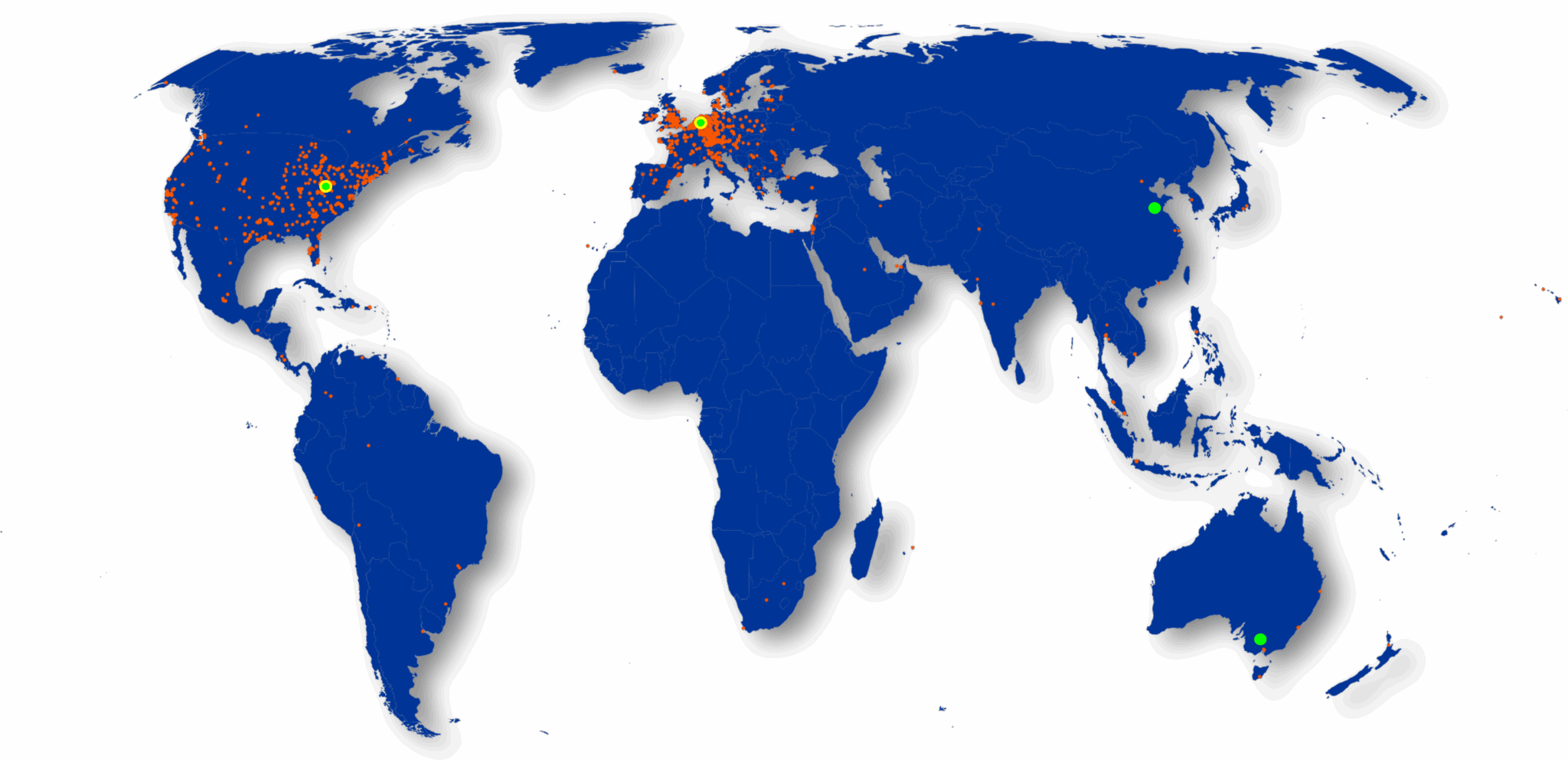

LINC® | Lantech Intelligent Network Connection® Option

LINC – an IoT solution is now available as an option on all Lantech Q, QL, S, and SL Automatic machines.

LINC allows subscribers to monitor machine data and performance in real time, from anywhere. It provides actionable intelligence and advanced analytics to support maintaining and improving system uptime, productivity, load quality, and cost, allowing customers to react to issues before they become problems.