Resource Library

All Featured

Review: Lantech Case Erectors and Their Applications

Case erecting automation is often the first major step companies take when […]

Learn MoreCase Erector Maintenance Requirements: Skills, Tools, and Preventive Care You Need

Automated case erecting is designed to reduce labor, improve consistency, and stabilize […]

Learn More3 Problems People Face When Starting to Automate Case Erecting

Automating case erecting is one of the most common first steps manufacturers […]

Learn MoreMaking Space for a Case Erector: How to Add Value with the Space You Have

For many operations and packaging managers, the idea of adding automation is […]

Learn MoreHow to Choose the Right Stretch Wrapper for a Large Warehouse

In large-scale warehouses and distribution centers, every process step—receiving, storing, picking, packing, […]

Learn MoreHow to Automate Pallet Wrapping in a Small Warehouse

For small and mid-sized warehouse operations, efficiency and cost control are paramount. […]

Learn MoreSemi-Automatic vs. Automatic Stretch Wrapper: Which One Should You Choose?

As demand for faster, more consistent, and safe-to-ship packaging grows across industries, […]

Learn More5 Benefits of an Automatic Case Sealer

As manufacturing and distribution facilities continue to look for ways to streamline […]

Learn MoreMost popular resources

Latest News

Lantech Expands Louisville Manufacturing to Include CS300 and CS1000 Case Sealers

Louisville, KY – November 4, 2025 – Lantech, a global leader in […]

Learn MoreLantech Introduces the Next‑Generation Semi‑Automatic Stretch Wrappers – SL400 and SL400LT

Louisville, KY – September 29, 2025 – Lantech, a global leader in […]

Learn MoreStill Setting the Standard: Lantech Unveils Cutting-Edge Packaging Innovations at Drinktec and PackExpo

Louisville, KY – Lantech, a trailblazer in the packaging industry, is thrilled […]

Learn MoreLantech demonstrates case handling for the bakery and confectionery industry at IBA

Malden, NL — Lantech, manufacturer of end-of-line packaging machines, will be exhibiting […]

Learn MoreGuides

4 Ways to Impact Sustainability with Film Optimization

Stretch film optimization is the fastest, lowest-risk way to reduce plastic today. In this guide, we highlight a few ways you can use film optimization to impact your sustainability efforts.

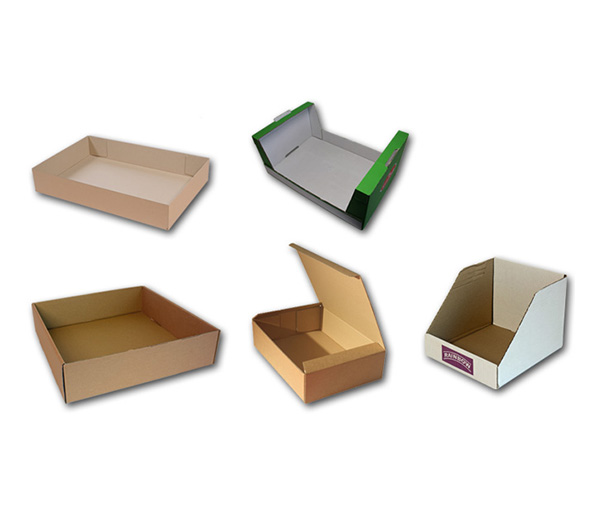

Read MoreTray Erector Buying Guide

A seamless packaging process is of invaluable value to companies striving for efficiency, speed, and consistency in their production. A tray erector can have a significant impact on your operational success.

Read MoreStop the Bleeding In the Paper-Based FMCG Industry’s Supply Chain

Reductions in primary and secondary packaging materials and ever-present cost reduction pressures are making most products more difficult to wrap. Fragile or delicate products like paper-based, fast-moving consumer goods (FMCG) are especially hard to wrap effectively.

Read MoreStretch Film Alternatives White Paper

Download this white paper to learn more about our evaluation into every currently stretch wrap alternative.

Read MoreCharts, Checklists And Calculators

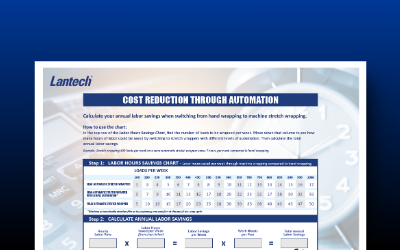

Calculator: Cost Reduction Through Automation

Calculate your annual labor savings when switching from hand wrapping to machine stretch wrapping.

DownloadCalculator: Automatic Case Erector Savings

Calculate your potential annual savings when switching from hand-erecting cases to automatic case erecting.

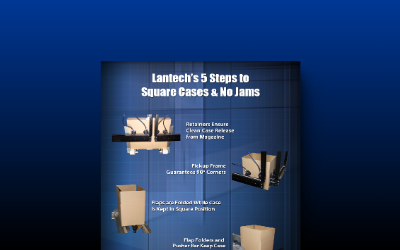

DownloadChart: 5 Signs of a Square Case

Learn five signs of a perfectly square case with this chart and let it serve as a reminder for the importance of square cases in pallet loading.

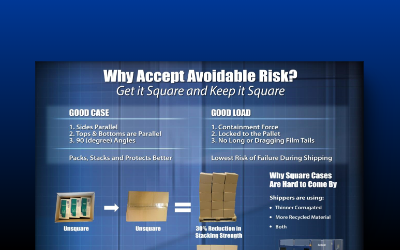

DownloadChart: Why Square Cases are Important

Find out why square cases are so hard to come by and how to identify one so you don’t have to take avoidable risks.

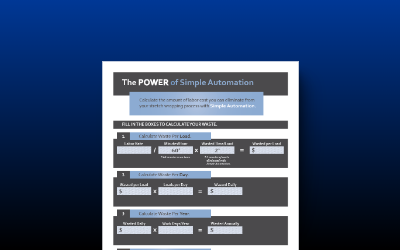

DownloadCalculator: The Power of Simple Automation

How much time and money are you wasting? Our calculator estimates the amount of labor cost you can eliminate from your stretch wrapping process with Simple Automation.

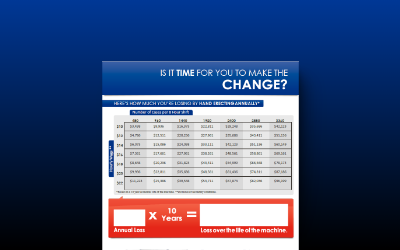

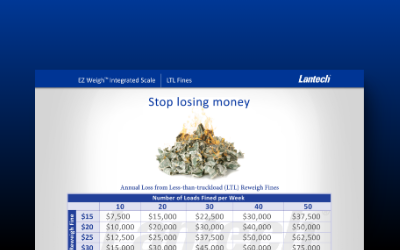

DownloadChart: Annual Loss From LTL Reweigh Fines

What does this mean for you? Download this chart to find out!

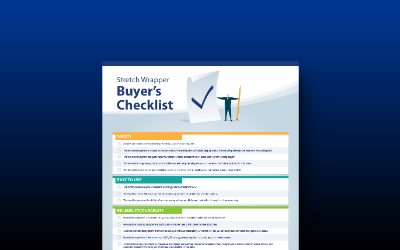

DownloadChecklist: Buying a New Stretch Wrapper

Run through the important safety, useability, reliability and effectiveness aspects of buying a new stretch wrapper with this checklist.

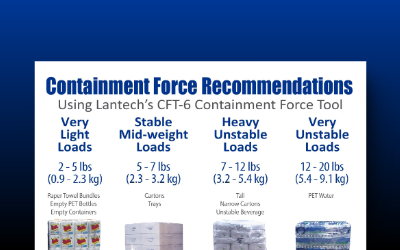

DownloadChart: Containment Force Recommendations

Your pallets face a rough ride as they ship to your customers. How they look when they arrive is an important part of your brand. Make sure they’re wrapped tight enough to survive the trip by checking their containment force.

DownloadQuizzes

Which Semi-Automatic Stretch Wrapper is right for you?

Take our short quiz to find out. Based on your answers, you will receive a suggestion as to which stretch wrapper would best suit your needs.

What kind of Case Erector fits your needs?

This short quiz can help you identify the type of case erecting machine that would work best for your facility.

Which Tray Erector best suits your situation?

Looking to optimize your tray erecting process? Take this short quiz to see the recommended tray erector machine to fit your needs.

Hotmelt versus tape calculator

Find out your payback period for choosing Hotmelt closure instead of Tape […]

Tray productivity calculator

Manually erecting trays takes time, adds labor costs, and can slow down […]

Case savings calculator

If you’ve been considering a case erector for your production line, here […]