FAQs

Frequently Asked Questions

Lantech makes stretch wrappers, case erectors, case sealers, tray erectors, lid formers and applicators, and conveying equipment.

No, Lantech case erectors do not erect cartons. Cartons are made from a single layer of thick paper stock, but are thinner and more lightweight compared to corrugated boxes. Examples of cartons would be milk or juice containers you see at the grocery.

Corrugated boxes are constructed using multiple layers of paper, usually consisting of two outer layers of linerboard and a middle layer of paper sandwiched between them in a fluted pattern. This design creates consistent air pockets, making it sturdy and resilient, and perfect for shipping products

Retrofits is the terminology we use for performance enhancing and labor saving options that can be added to existing Lantech equipment. Retrofits help customers extend the lifespan of their equipment by improving performance, enhancing productivity, and incorporating new features or technologies to meet evolving packaging needs.

James J. Lancaster is the President and CEO of Lantech.

Lantech is a private, family owned business. Lantech is owned by the Lancaster family in Louisville, KY.

Yes, Lantech’s culture makes people feel good about coming to work every day and tackling challenges together. It’s a work family based on loyalty and respect. The loyalty of a family-owned and operated company to do what’s best for its employees, and employees who, in turn, always focus on what’s best for the customer. Lantech has a culture of mutual respect that is pervasive from the receptionist’s desk to the factory floor, to management, and naturally extends out to our customer base.

See our job opening on our Job Opportunities page.

If you do not have or know your Lantech equipment supplier please contact us and we can provide you with suppliers in your area.

Lantech sells equipment though third party distributors and system partners and direct to National Accounts.

Lantech has over 750 employees globally.

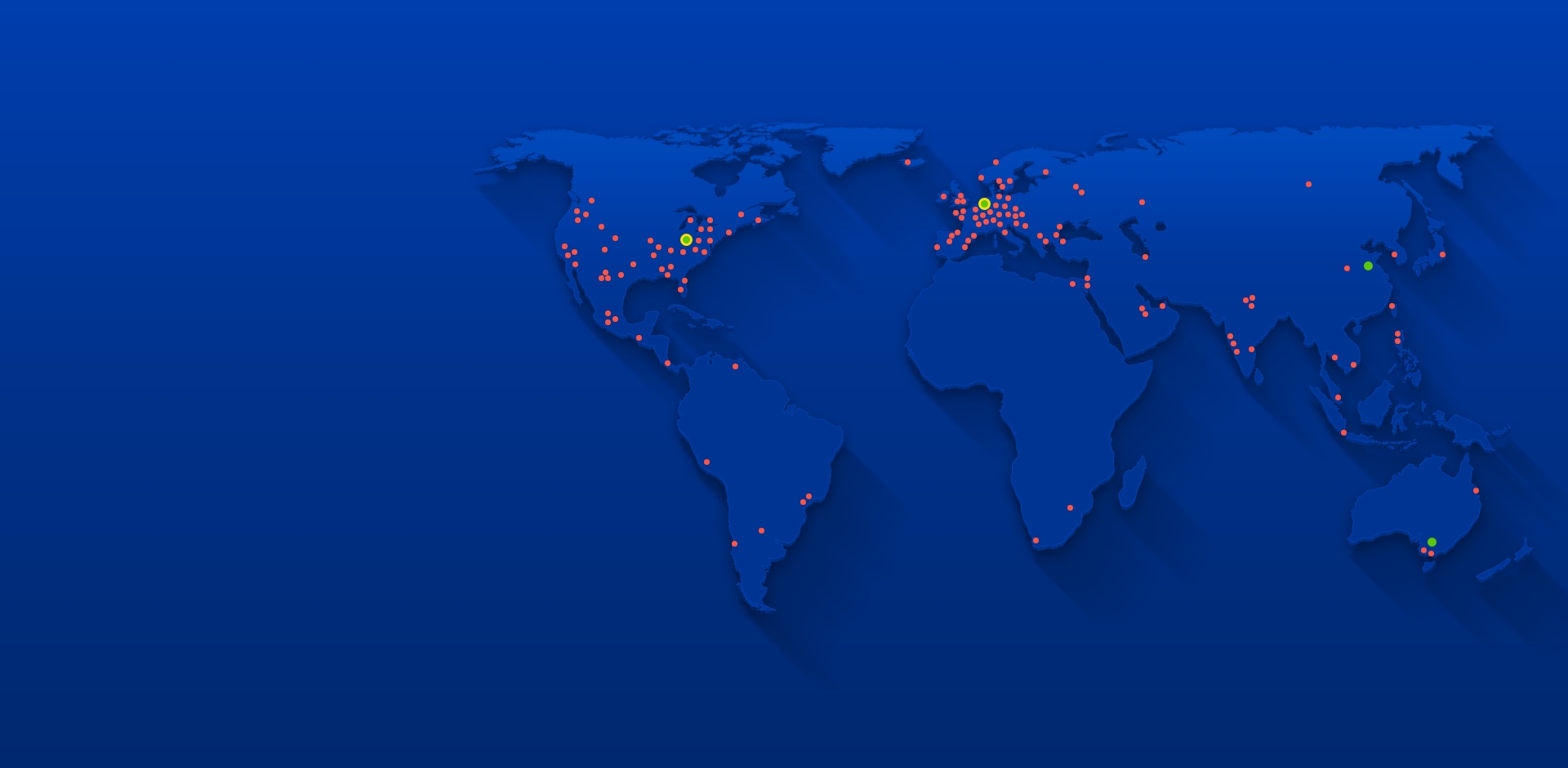

Lantech manufactures its equipment in Louisville, KY USA and in Malden, Netherlands.

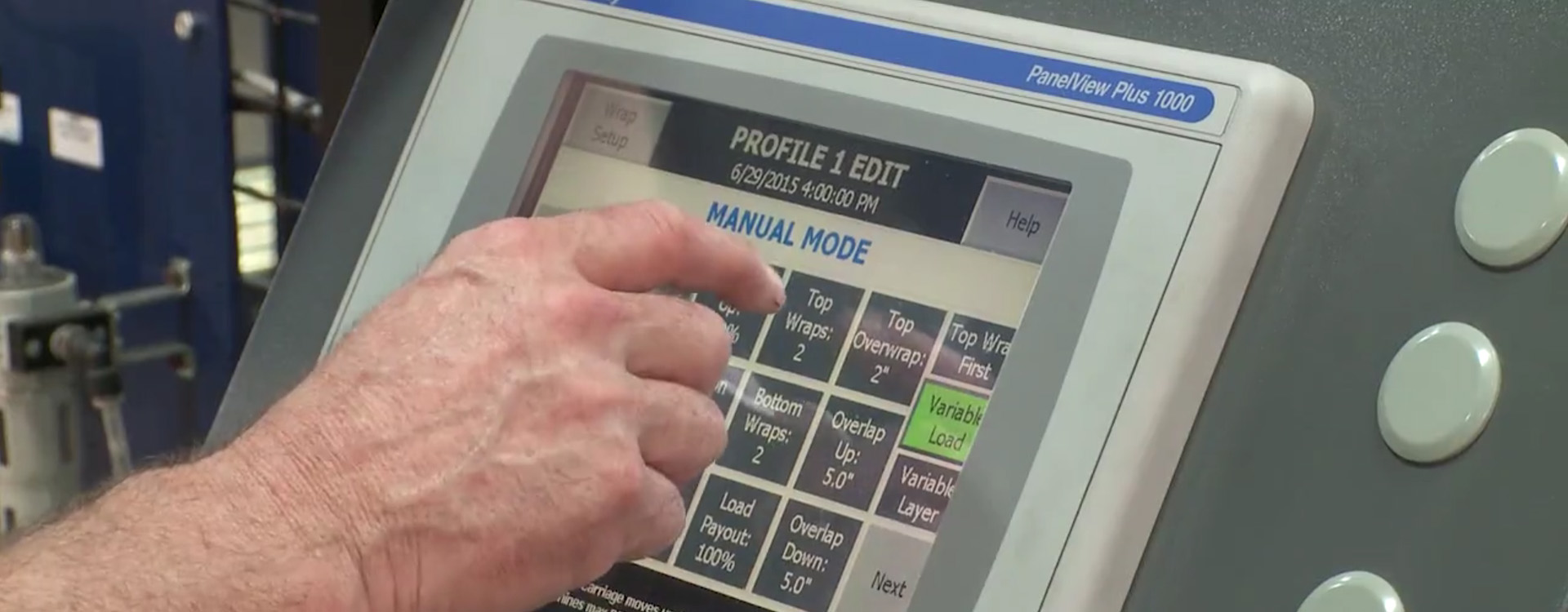

LINC® | Lantech Intelligent Network Connection is Lantech’s proprietary IoT machine data visibility solution designed to provide real-time monitoring, control, and optimization of packaging operations, enabling data-driven decision-making and improved productivity.

LINC®️ will appear on quotes as a suggested option for all new LeanWrap® Automatic Stretch Wrappers and Modular Case Erectors. It can be purchased with your new machine order or retrofitted on a machine you already own.

As many users as you need underneath a single administrator. You can add, modify, or delete users at any point directly from the LINC® portal.

Contact our sales team by requesting a quote for more information or a product demo.

LINC®️ is Compatible with all Lantech LeanWrap® Automatic Machines* (serial numbers beginning with RLA, QLA, SLA, or SLC). It is also compatible with Inline and C-Modular Case Erectors* (C1000 & C2000, CI1000 & CI2000, MFCE, Any Case Machine with Siemens or Rockwell PLC’s.

Yes, retrofits are available for all field equipment compatible with LINC (Lantech LeanWrap® Automatic Machines and Inline and C-Modular Case Erectors). Contact us about a retrofit opportunity on your existing machine by requesting a quote.

Lantech was founded in 1972 by Pat Lancaster and his brother Bill, with a vision to revolutionize the packaging industry through innovative solutions.

1972: Lantech was founded by Pat Lancaster and Bill Lancaster.

1972: The first rotary arm stretch wrapper was introduced to the market

1995: Jim Lancaster, son of Lantech co-founder Pat Lancaster, became Lantech’s President and CEO

1993: The Q-Series semi-automatic stretch wrapper was introduced

2001: Lantech purchased the Rembrandt Company – a manufacturer of case & tray handling equipment in the Netherlands

2009: The first LeanWrap Automatic stretch wrappers were introduced

2013: The ProfitPack semi automatic packing line was introduced

2016: The CI Modular Inline Case Erector was introduced

2017: The QL400 Semi-Automatic stretch wrapper was launched with Load Guardian

2018: Lantech Netherlands moved to new facility in Malden, Netherlands to allow for production expansion

2020: The MFC Modular Multi Format Case Erector, with up to 4 blank magazines, was introduced

2023: Lantech’s headquarters in Louisville, Kentucky was expanded to include the production of case equipment in the USA

2024: The Parcel Tray Erector and Lid Applicator, designed for letterbox size packages, was introduced

Lantech has manufacturing facilities in the United States and the Netherlands, and sales and technical support worldwide. Please visit our Contact Us page for location information

Factors to consider include load type, production volume, space availability, load stability requirements, and budget.

Stretch wrapping ensures load stability, protection from damage during transit, and efficient handling of goods, leading to cost savings and improved supply chain efficiency.

Stretch wrapping securely binds loads together, minimizing movement and shifting during transit, reducing the risk of load damage.

Common types include:

- Turntable stretch wrappers – Loads are placed on a turntable which rotates to allow the stretch film to be wrapped around the load. Turntable stretch wrappers are suitable to wrap most types of loads.

- Rotary arm stretch wrappers – Loads are placed on the ground, and a rotary arm wraps around the load to apply stretch film. Rotary arm stretch wrappers are perfect for heavy, light, tall or unstable loads.

- Orbital stretch wrappers – Also known as rotating horizontal ring wrappers. Loads move along a conveyor through a horizontal ring to be wrapped. Orbital stretch wrappers are perfect for long or oddly shaped products.

Automatic stretch wrappers require little-to-no operator intervention, while semi-automatic wrappers involve some manual input and/or interaction at the beginning and/or end of the wrapping process.

Questions about film should be directed to your film supplier.

Pre-stretching stretch film improves film yield, enhances load containment, reduces film usage and costs, and ensures consistent wrapping tension throughout the load.

Stretch wrapping offers superior load containment, flexibility to accommodate various load shapes and sizes, and reduced material and labor costs compared to strapping or banding.

Yes, Lantech stretch wrapping equipment can be customized with various options such as scale integration, top sheet application, extended towers for taller loads, and many more, all designed to meet specific production requirements.

Stretch wrapping optimizes material usage, reduces packaging waste, and minimizes the environmental impact associated with transportation, making it a sustainable packaging solution.

Automation streamlines wrapping operations, improves consistency and efficiency, reduces labor costs, and enhances overall productivity in packaging and distribution operations.

Stretch wrapping involves applying a stretch film around a load to secure and stabilize it during transit, utilizing the film’s elasticity to create tension. Shrink wrapping, on the other hand, involves using heat to shrink a plastic film tightly around a product or load, conforming to its shape. Stretch wrapping is more commonly used for palletized loads and offers flexibility to accommodate various shapes and sizes.

The Lantech Total Control System provides 100% precise control of blanks during the entire forming process, delivering perfectly square cases without jamming, and overcomes manufacturing variations that are common in case blanks.

Case erectors are machines that automatically form and fold corrugated cases, streamlining the packaging process by eliminating the need for manual case assembly, increasing throughput, and reducing labor costs.

Lantech case erectors are versatile and can handle various case sizes, styles, and configurations, including regular slotted containers (RSC), half-slotted containers (HSC), and more, accommodating a wide range of packaging needs.

Case sealers apply adhesive tape or hot melt glue to securely seal the top and bottom flaps of corrugated cases, ensuring product integrity, tamper-evident packaging, and efficient throughput in the packaging line.

Factors to consider include tray size and style, production volume, tray material compatibility, footprint space, ease of integration with existing equipment, and flexibility to handle various tray designs.

Tray erectors automate the forming and loading of trays, ensuring consistent tray dimensions, neat presentation, and enhanced product visibility on retail shelves, which can positively impact consumer purchasing decisions.

Lid applicators are machines designed to automatically apply lids or covers to trays or cases, increasing packaging speed, reducing labor costs, and ensuring secure closure of packaged products.

Yes, lid applicators are designed to handle cardboard lid types and can adjust to different lid sizes and shapes to meet specific packaging requirements.

Integration of tray and lid handling equipment into a fully automated packaging line enhances efficiency, consistency, and reliability of the packaging process, reduces labor costs, and improves overall production throughput.

Yes, Lantech offers customization options for tray and lid handling equipment, including adjustable settings, tooling configurations, and integration with other packaging machinery, to meet unique packaging needs and specifications.

Lantech equipment is designed with energy-efficient features such as servo motors, variable frequency drives, and intelligent controls, reducing energy consumption, minimizing environmental impact, and supporting sustainable packaging initiatives.

The Lantech Built Tough Warranty gives you bumper-to-bumper, unlimited cycle coverage. We also provide a full 1-year warranty on all purchased replacement parts. Warranty Extensions are now available for new machines and existing machines currently within their original warranty periods. Visit our Warranty page to learn more.

Yes, Lantech offers training programs tailored to the specific needs of equipment operators and maintenance personnel, covering topics such as equipment operation, troubleshooting, maintenance best practices, and safety protocols. Visit our Training page to learn more.

Customers can download or request a manual for their machine, no matter when it was purchased by visiting our Manuals page. Customers can also request parts lists, technical documentation, and machine drawings for Lantech equipment from our helpful Parts Team.

Yes, Lantech provides 24/7 support for equipment emergencies, ensuring rapid response and resolution of critical issues to minimize downtime and maintain production continuity for customers. Contact us now from our Service page.

Lantech’s after-market services, including training, parts availability, retrofits, upgrades, and round-the-clock support, are designed to maximize equipment uptime, optimize performance, and protect customers’ investment in their packaging machinery.