The easiest and most cost effective way to create square cases is to do it with a case erecting machine. Case erectors pull blanks from a magazine, square the box and tape the bottom flaps to form 90 degree angles on all sides.

Just like knowing the fundamentals of a sport is essential to becoming a great player, creating a square case is fundamental to preparing products for successful shipment. Here’s why:

1. Square cases are easier to pack.

Whether you’re using an automated case packer or packing cases by hand, it’s easier to do when the case is square. It’s important to pack products securely so the primary packaging is less likely to be damaged during shipment.

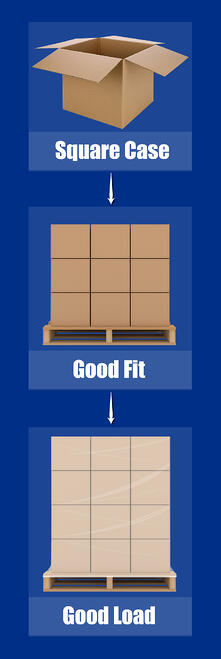

2. Pallets built with square cases stack better.

When the corners of a case are aligned properly, they’ll support more weight. If they’re not square, the cases are unstable and more prone to being crushed. In fact, when cases are stacked on a pallet and the sides aren’t aligned, the load loses 30 percent of its stacking strength, making it more susceptible to damage.

3. Square cases protect your products better.

When cases are square they stack better on a pallet – which makes them easier to effectively stretch wrap. Loads go through a lot of stress during shipment. All the starting and stopping, vibrations and bumps will take a toll. Square cases make loads that fit better inside the perimeter of a pallet. Boxes that hang over the sides of the pallet can be damaged by a fork lift or crushed against another load or truck wall.

Building square cases by hand isn’t as easy as you might think. It can be difficult to tape box after box perfectly. If you’re spending money on corrugate you want to make sure it’s doing the job you intended it to do. A good case erector can provide the consistency people lack.

This post was published on August 10, 2020 and updated on August 10, 2020.

August 10, 2020