In recent years, the concept of the circular economy has gained significant attention to transition towards a more sustainable and resilient economy. The circular economy is a regenerative system that aims to keep resources in use for as long as possible, eliminate waste, and minimize the consumption of new resources. One sector that can benefit from the principles of the circular economy is the stretch film industry. In this blog post, we will explore how stretch film sustainability can be improved through the adoption of circular economy principles.

Stretch film is commonly made of polyethylene, a type of plastic that is lightweight, flexible, and durable. However, the production and disposal of stretch film can have significant environmental impacts. According to the Ellen MacArthur Foundation, only 14% of plastic packaging is collected for recycling globally, and even when it is collected, the quality of the recycled material is often low. However, alternatives also have damaging effects on the environment and in most cases are more damaging than virgin resin alone (see Lantech’s Film Alternatives Project).

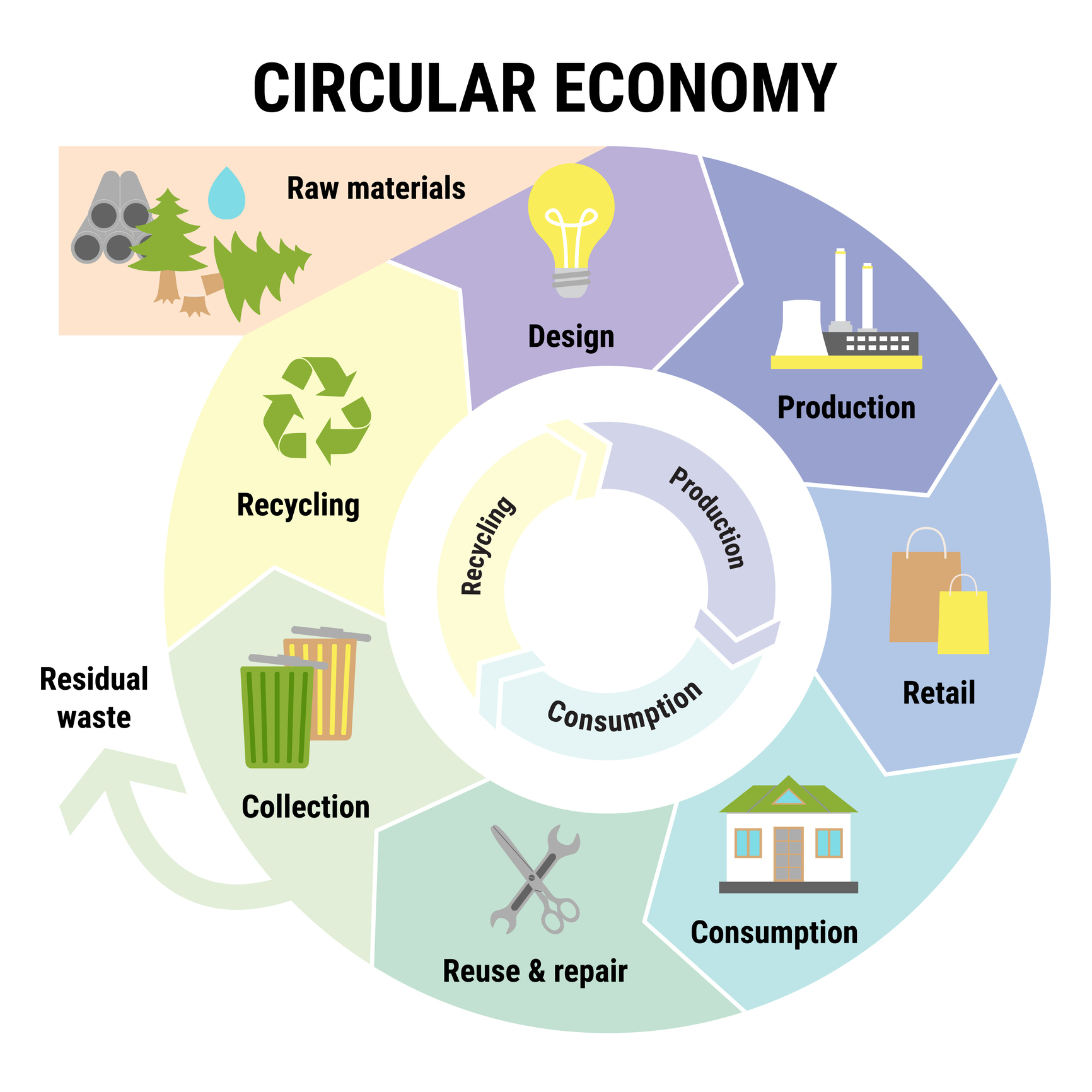

To address these challenges, the circular economy offers a promising approach. The circular economy is based on three principles: designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. These principles can be applied to the stretch film industry in the following ways:

1. Designing out waste and pollution: The first step in creating a circular economy for stretch film is to design out waste and pollution. This can be achieved by reducing the amount of packaging used with better wrapping technology and ultra grade films that use very small gram weights to achieve desired containment.

2. Keeping products and materials in use: The second principle of the circular economy is to keep products and materials in use for as long as possible. This can be achieved by designing and implementing a closed-loop system where used stretch film is collected and recycled into new products. Unfortunately, stretch film is a highly temperamental application and any impurities in PCR film will severely inhibit performance and sustainable outcomes. Therefore, a film waste capture system in the near term might consider recycling into other downstream products (such as garbage bags).

3. Regenerating natural systems: The third principle of the circular economy is to regenerate natural systems by using renewable energy sources and minimizing the use of non-renewable resources. In the case of stretch film, this can be achieved by using renewable energy to power production processes, and by designing stretch film and collection processes that allow for easy recycling into new products without creating harmful waste or pollution.

In conclusion, the circular economy offers a promising approach to improve stretch film sustainability. Our Film Alternatives Project compliments a “design out waste” approach. In the project, we explain how optimizing wrapper technology and leveraging ultra grade virgin films could be the most fruitful and feasible near-term strategy for achieving sustainable packaging goals. By designing out waste and pollution, keeping products and materials in use, and regenerating natural systems, companies can create a more sustainable and resilient stretch film industry. By adopting these principles, we can move towards a more circular and sustainable economy, one that benefits people, the environment, and the economy.

If you would like to learn more about our Film Alternatives Project, join us at Interpack, the world’s largest packaging and processing trade fair. As an industry leader, we’d like to offer you a free ticket to attend. This is your chance to network and learn about the latest industry trends and innovations.

The event will take place from May 4th to May 10th, 2023, at the Düsseldorf Trade Fair Centre in Germany. With over 170,000 visitors from 170 countries and 2,800 exhibitors, it’s a must-attend event. To claim your free ticket, click here and fill in your details. We look forward to seeing you there!