One of the driving motivations behind lean manufacturing is the elimination of waste. By eliminating waste, getting to the root of problems, lean manufacturing helps manufacturers reduce costs and increase productivity. These core concepts have led businesses from all industries to adopt lean techniques, and one of the key players in the world of lean manufacturing is Jim Womack.

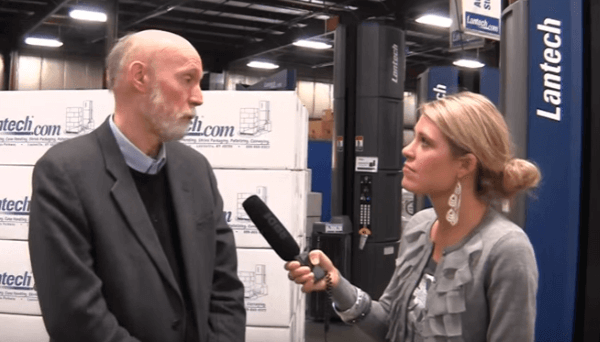

A few years ago, we spoke with Jim Womack and asked him a questions about lean manufacturing.

A few years ago, we spoke with Jim Womack and asked him a questions about lean manufacturing.

The interview begins with a look at Toyota’s approach to lean, looking for ways to reduce costs while maintaining customer value and quality. Jim then talks about community PDCA, what it is, and how to get involved.

He also discusses lean thinking, creating more value with less and how that thinking evolves with customers’ needs and changing industry challenges.

5 Good Questions with Jim Womack

Watch the interview below:

You May Be Interested in These Related Posts

- Understanding Forklift Costs – Capital, Maintenance, and Fuel

- Stay Relevant or Lose: What Baseball and Lean Businesses are Doing

- 7 Types of Waste in Lean Manufacturing

This post was published on January 17, 2017 and updated on April 12, 2017.

January 17, 2017